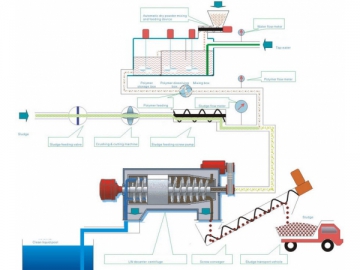

Sludge Dewatering Unit

Sludge dewatering unit is specially designed for sludge concentration and dewatering. This sludge dewatering equipment comprises LW horizontal decanter centrifuge, fully automatic polymer mixing and feeding device, sludge crushing and cutting machine, as well as sludge feed pump, polymer feed pump, shaft-free screw conveyor, flow meters, control valves and fully automatic control system, etc.

This municipal wastewater treatment system is highly characterized by advanced structure, optimal configuration, high automation, continuous and closed workflow, as well as safe and reliable performance, etc. This chemical wastewater cleaning solution has been extensively applied to industries of municipal, chemicals and pharmacy, etc.

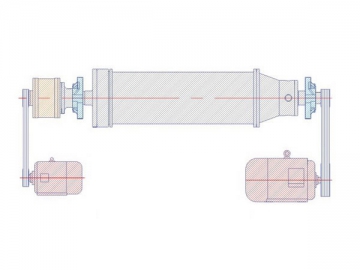

Main Components and Workflow Diagram of Sludge Dewatering Unit

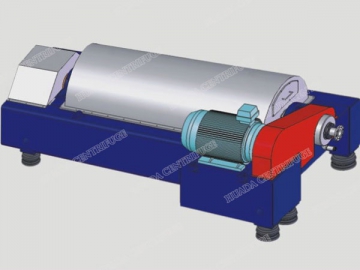

LW Horizontal Decanter Centrifuge

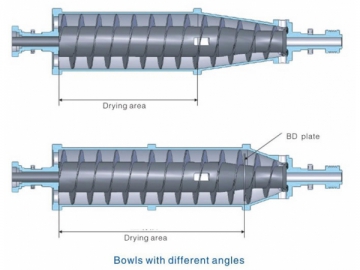

LW horizontal decanter centrifuge is one of the most essential components to our sludge dewatering unit. This part is endowed with remarkable conical angel, baffle disc (BD) and considerable L/D ratio, as well as large-torque planetary differential gear or hydraulic driving system. As a result, our pharmaceutical wastewater handling equipment is renowned for high speed, large torque and small gear ratio.

Main Features

1. High Speed

High bowl rotating speed comes with impressive centrifugal force, ensuring our sludge dewatering unit to be applicable for fine particles ≥3μm.

2. Large L/D Ratio

Actual bowl length and diameter ratio is no less than ≥4.1. Large sedimentation area prolongs time of sludge clarification and dewatering.

3. Baffle Disc (BD)

Baffle disc is the round plate deposited between sedimentation section and drying section. Sludge, which comes from sedimentation section, is pressed into drying section for lower moisture rate. Moreover, BD also isolates sludge from polymer. Pond depth is larger than solid discharge.

Bowls with Different Angles

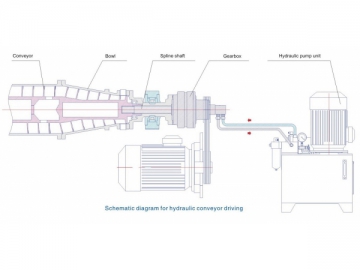

Driving Technology

Our centrifuge adopts various driving systems to practically handle different substances. The bowl driving system consists of AC motor and variable frequency drive. The driving system for scroll falls into the combination of AC regeneration variable frequency drive and multiple-stage planetary gearbox, as well as hydraulic driving system with independent hydraulic pump.

- Common DC Bus Drive

- Differential System for Hydraulic Scroll Drive

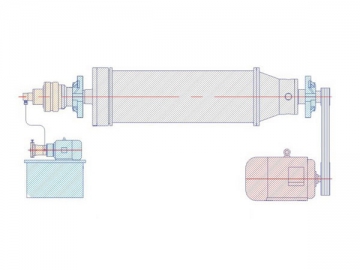

This hydraulic drive is the sealed power system comprising bowl and scroll, and independent from bowl driving system. This drive is different from other mechanical systems by being free from assistance of bowl rotation for differential speed. It is directly deployed on scroll assembly and is powered by independent hydraulic pump aggregate.

Working Principle of Hydraulic Scroll Drive

The housing of hydraulic scroll differential gear is connected with bowl for rotation at same high speed. Splined shaft on differential gear rotor connects with scroll which rotates at different speed from bowl. As a result, differential speed Δn is generated.

The connection between scroll differential gear and hydraulic pump aggregate is maintained by high-pressure hose, thus no gearbox is needed between bowl and scroll. Moreover, scroll torque delivers pressure on hydraulic system, based on which the change of differential speed is determined by adjustments on oil supply. In addition, differential speed is displayed on pump aggregate and scroll differential gear, and allows for remote reading.

Main Features of Hydraulic Scroll Drive

1. No gear transmission device

2. Free from part crack by overload

3. No vibration

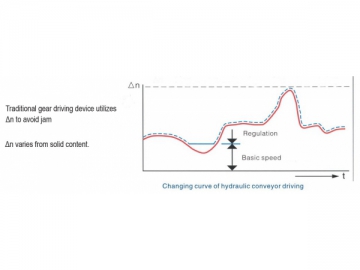

4. Directly readable torque and differential speed Δn

5. Δn is independent from bowl speed.

6. Constantly minimized cake moisture

7. Processed liquid in high clarity

8. Power for solids conveying varies from solid content.

9. Dewatering process varies from different Δn.

10. Impressive feeding capacity minimizes feeding jam.

11. Safety pin ensures safe operation.

Working Principle Diagram of Hydraulic Scroll Drive

Graph of Differential Speed of Hydraulic Scroll Drive

Technical Parameter of LW Horizontal Decanter Centrifuge

| Item | Model | |||

| Bowl Dia. (mm) | 350 | 450 | 530 | 630 |

| Max. Speed (r/min) | 4000 | 3200 | 2800 | 2500 |

| Centrifugal Force | 3100 | 2580 | 2300 | 2205 |

| Processing Capacity (m3/h) | 8-15 | 20-35 | 30-50 | 40-80 |

| Main Motor Power (kW) | 22 | 30 | 55 | 75 |

| Cake Moisture Content (%) | 68-80 | |||

| Solids Recovery (%) | ≧95 | |||

Electronic Control System

Main Features

1. Our sludge dewatering unit involves the utilization of PLC to perform fully automatic or manual control on feeding pimp, cutting machine, flow meters as well as polymer dosing and feeding device, etc. It also carries out functions of detection, failure alarm and interlock protection, etc.

2. Automatic control is conducted in accordance with pre-set configuration to perform start-up, separation, cleaning and shut down of centrifuge.

3. Feeding amount can be automatically adjusted at constant torque.

4. According to change of feeling torque, automatic adjustment is conducted on differential speed to avoid feeding jam.

5. Automatic adjustment is applied to oil supply on the basis of hydraulic pressure changes, so that to control differential speed.

6. Automatically mixing and dosing of polymer as required

7. Large-size color touch screen is available to display real-time operation status.

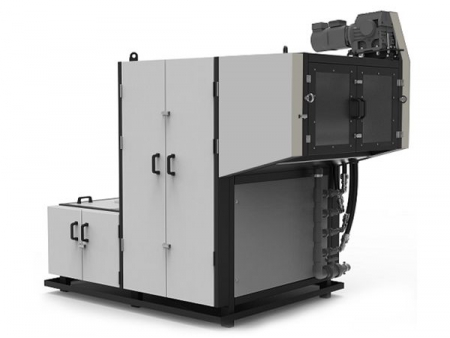

Polymer Mixing and Dosing Device

This polymer mixing and dosing device is the latest three-chamber supplier of macromolecule polymer. It is ruggedly engineered for automatic production of 1-3‰ PAM (Polyacrylamide) based flocculants, as well as automatic calculation of weight of supplied flocculants and water flow rate. Therefore, our sludge dewatering unit benefits from continuous supply of flocculants.

This device comprises automatic dry polymer feeding system, automatic water dosing device, level monitoring system and mixing device, as well as pipeline and valves, etc.

Note

HUADA also is capable of offering two chamber polymer mixing and dosing device.

Technical Parameter of Polymer Mixing and Dosing Device

| Items | Model | |||

| Concentration (‰) | 1-3 | 1-3 | 1-3 | 1-3 |

| Preparation Capacity (m3/h) | 1 | 2 | 5.5 | 5 |

| Motor Power (kW) | 2.2 | 2.2 | 2.5 | 2.5 |

Sludge Crushing and Cutting Machine

This machine is involved in our sludge dewatering unit to break down large particles contained in sludge (particle content≤5) such as wood block, textile, plastic, rubber, bone, leather and glass, etc. As a result, constant normal operation can be ensured to feeding pump, decanter centrifuge and instrument in the downstream. In addition, this machine features large capacity and blade with long lifespan.

Helical Rotor Pump

The helical rotor pump features positive displacement, large transmission distance, great teach height and scroll with small inner diameter. Feeding progress axially commences from the suction to the discharge port of pump. Highly abrasion resistant material is used to transport 0.2-5% solid content sludge and polymer. Flow rate is controlled by variable frequency drive.

Shaft-free Scroll Conveyor

LS Shaft-free scroll conveyor generally comprises drive unit, shaft-free helical blade, U-shaped changeable abrasion-resistant lining plate and equipment frame. This device is applied to convey dewatered cake from our sludge dewatering unit to outdoor warehouse or transport vehicles. The entire progress is conducted in enclosed status to keep clean environment.

Technical Parameter of Shaft-free Scroll Conveyor

| Items | Model | ||

| Helical Blade Dia. (mm) | 240 | 300 | 400 |

| Convey Capacity (m3/h) | 2-5 | 5-8 | 12-15 |

| Rotating Speed (r/min) | 16 | 16 | 12 |

| Convey Angel (°) | 0-30 | 0-30 | 0-30 |

| Motor Power (kW) | 2.2 | 3 | 4 |