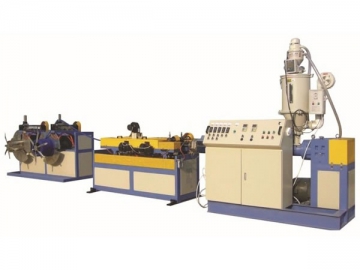

PE/PP/PVC Single Wall Corrugated Pipe Extrusion Line

This corrugated pipe extrusion line mainly uses the PVC, PP, and PE as raw materials to produce small-size single-wall pipes with ridges and grooves on their surface. The smallest diameter our corrugated pipe production line can produce is 4.5mm and the corresponding equipment model number is SJ-30. The largest allowable diameter is 63mm and produced by model SJ-65.

Unique to our corrugated pipe extrusion line is the extrusion die which allows 2 or 3 diameters of pipes to be produced at one time while forcing them through the same die. The versatility of our extrusion die reduces the number of dies needed for producing pipes of different diameters. It also saves much time that otherwise would’ve been spent on changing dies, thereby improving production efficiency. Pipes extruded from this extrusion equipment are corrugated on the exterior and smooth on the interior, exhibiting great resistance to high temperature, corrosion, and abrasion.

Applications

The single wall corrugated pipe made by our corrugated pipe extrusion line is commonly used as the electrical conduit and protective casing in machine tool parts, packaged food machinery, electric locomotive, installation project, luminaries, and automated instruments industries.

Features

1. Optimized design of extruder screw and die makes it easier for users to change the die. The gear teeth have been through surface hardening process to obtain enhanced wear resistance. Imported ABB variable frequency drive controls the rotating speed of extrusion screw on the corrugated pipe extrusion line. All theses features ensure raw plastics is heated uniformly and fast extruded to form quality extrusions. They solve the problem of easy wear on the extruder barrel and difficulty in extrusion shape formation.

2. Enclosed structure is designed to handle full vacuum applications. The extrusion die is powered by the motor via a gearbox. It is provided with water cooling system.

3. Corrugated pipe is fast produced and effectively cooled through air cooling.

| Model No. / Specifications | Pipe Diameter Range(mm) | Extruder Model No. | Number of Extrusion Dies(pairs) | Cooling Method | Production Speed(m/min) | Maximum Production Rate(Kg/h) | Installed Power(KW) | Dimension(m) | Weight(t) |

| 8-25 | 38 (40) | Air cooling, water cooling | 1-12m/min | 40 | 30 | 8.5×1.2×1.7 | 5.5 | ||

| 16-50 | 42 (44) | Air cooling, water cooling | 1-10 m/min | 80 | 60 | 12×1.2×1.7 | 7.5 |