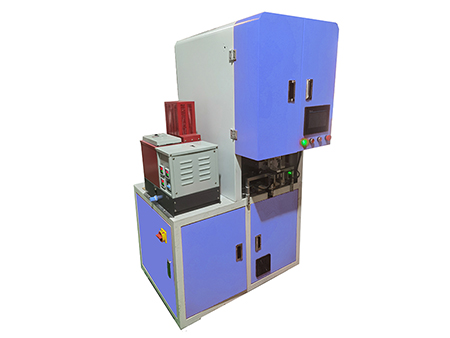

Automatic Notching Machine, LY-900KC

Request a Quote

Used for rigid box manufacturing

The automatic notching machine is designed specifically for cutting V-shaped grooves into various types of industrial cardboards and greyboards. The cardboard should be covered on the roller with a diameter of 60 cm to ensure the groove is cut accurately without any deviation.

This automatic notching machine is suitable for cutting grooves on the cardboards making two-piece boxes, book-style boxes, wine boxes, phone boxes (for electronic products), jewelry boxes, and mooncake boxes.

Sample BoxesFeatures

- High Precision

The notching machine uses an automatic paper feeding system to ensure a precise delivery of boards. Thanks to its automatic deviation correction of single-side alignment, the notching machine provides a 50% increase in precision compared to double-side alignment machines, eliminating the instability issues that come with manual board delivery. - High Speed

Powered by a continuous paper feeding mechanism, pressure rollers enable the milling process to be completed in a single pass. - Durable Tools

The cutting tools that come with the notching machine are sharp and exceptionally durable, thanks to their resistance to wear and tear. - Double-layered Material Collection

For easy waste management, the notching machine features a double-layered material collection system. The upper layer collects finished products, while the lower layer sends waste material from the four corners of the board to the back of the notching machine for disposal.

| Infeed Paper Width | 120-850 mm |

| Infeed Paper Length | 120-400 mm |

| Maximum Accuracy | 0.05 mm |

| Standard Accuracy | ±0.1 mm |

| Maximum Manufacturing Speed | 30-32 m/min, 110-120 pcs/min (work piece size 200*200 mm) |

| Standard Manufacturing Speed | 20-25 m/min |

| Grooving Angle | 80°-140° adjustable |

| Cardboard Thickness | 300 gsm-3.5 mm |

| Number of Grooves Notched at the Same Time | 9 |

| Rated Power | 3.0 kW |

| Waste Collection | Automated |

| Finished Product Collection | Collecting from the same direction on both layers |

| Positioning Accuracy | Bi-directional precision positioning |

| Weight | 1480KG |

| Overall Size | 2100*1400*1350 mm |

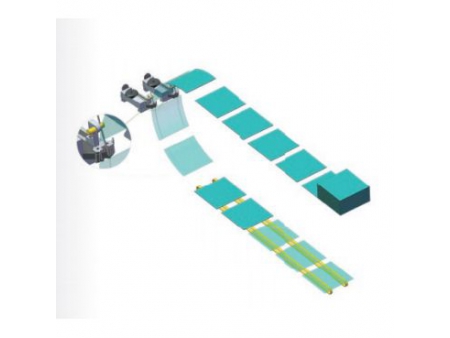

Other Equipment of Rigid Box Line

There are some box making Equipment that we featured for choose your best

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos