Raymond Mill

Request a Quote

Description

The Raymond mill is widely used for grinding non-flammable and non-explosive materials whose hardness is below 9.3 and humidity is less than 6% such as barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite and lime, activated clay, activated carbon, betonies, kaolin, cement, phosphate rock, gypsum, glass and thermal insulation in the mining, metallurgy, chemistry and building industries.

The Raymond mill is widely used for grinding non-flammable and non-explosive materials whose hardness is below 9.3 and humidity is less than 6% such as barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite and lime, activated clay, activated carbon, betonies, kaolin, cement, phosphate rock, gypsum, glass and thermal insulation in the mining, metallurgy, chemistry and building industries.

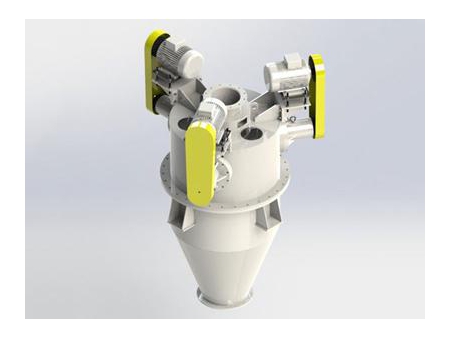

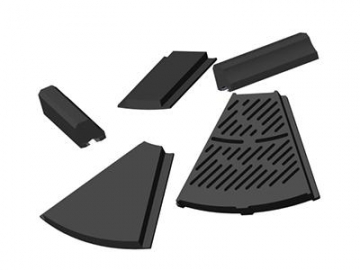

Structure

This coal equipment is composed of a main engine (with a rack, inlet air volute, relieving tool, grinding roll, grinding ring, and cover piece), analytical engine, air blower, clone separator for final products, clone separator for micro powders and air pipe.

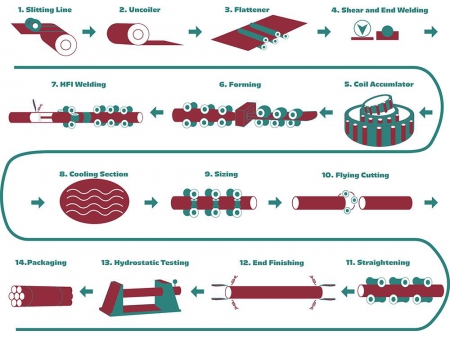

Working Principle

Material is fed into the Raymond milling machine through the feeding hopper. The grinding roll that hangs on the main engine rotates around the vertical axis and itself. Centrifugal force makes the grinding roll swing outward and press onto the grinding ring, scooping up material and grinding it between the roll and the ring.

| Model | | |||||||||

| Max feeding size (mm) | 10-15 | 10-15 | 10-15 | 15-20 | 15-20 | 20-25 | 15-20 | 20-25 | 20-25 | 20-30 |

| Output size (mesh) | 60-325 | |||||||||

| Shift output (t/8h) | 1-10 | 1.3-14 | 1.5-16 | 2-24 | 2-29 | 3-34 | 2-31 | 3-35 | 3-39 | 5-66 |

| Roller diameter (mm) | 140 | 180 | 210 | 260 | 270 | 300 | 270 | 300 | 320 | 410 |

| Main power (KW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 22 | 30 | 37 | 75 |

| Blower power (KW) | 5.5 | 7.5 | 11 | 18.5 | 18.5 | 22 | 18.5 | 22 | 30 | 75 |

| Analyzer power (KW) | 1.1 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 5.5 | 7.5 |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos