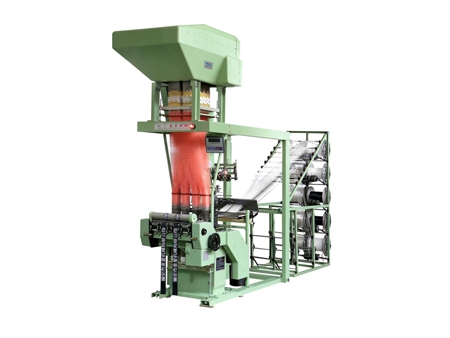

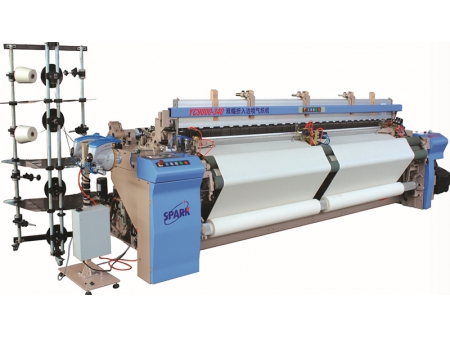

Air Jet Loom

Our air jet loom features high speed, outstanding performance and high intelligentization. This product can be employed for weaving various kinds of textiles made of cotton, chemical fibre, filament, fibre, and some others, in the patterns of tabby, twill, satin weave, dobby, jacquard fabric, etc.

The weft insertion is conducted through the utilization of compression air. Since the weft yarn is not held by the machine, our SA810 series air jet loom is characterized by fast operation speed, outstanding weaving quality, small material consumption, high automation, high mechanical efficiency, small vibration, low noise, and convenient maintenance. Professionally designed, the simple and elegant appearance of our weaving machine may bring you completely new visual enjoyment.

Advantages

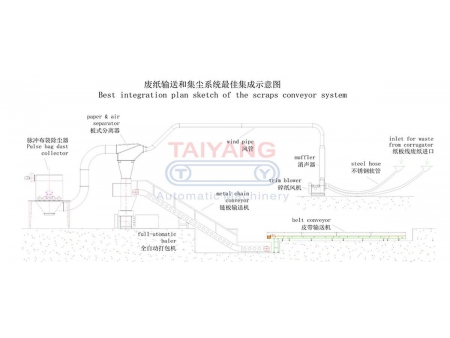

1. Energy-saving weft insertion system

The weft inserting system is consisted of boost pressure master nozzle, swing mater nozzle, auxiliary nozzle, and draft nozzles. Every three auxiliary nozzles are controlled by one auxiliary solenoid valve, which is installed on the top gas pocket of the air jet loom. So the gas consumption can be reduced by 20%. The weft insertion angle can be automatically regulated by computer, reducing energy consumption by 10%. Additionally, the special shape reed is adopted.

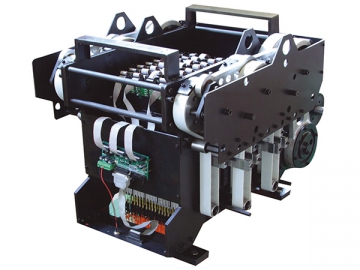

2. New type electronic control system

The new type electronic control system can be used to monitor the operation of the air jet loom. To offer optimal weaving process, this pneumatic loom is provided with automatic setup function to adjust the process technology for different warps and wefts, according to the warp tension, nozzle degree, and other related information.

Additionally, the automatic time control device for weft insertion can regulate the opening degree of magnetic needle as well as the angle of the injection valve, making the actual arrival time of the weft close to that is set. Moreover, ideal weft insertion setup can be realized, accordingly.

3. Sturdy rack configuration

The rack for energy-saving air jet loom is consisted of new type integrated wallboard and the beam made of rectangular tube with outstanding torsion resistance. Even operating at high speed, our product can run stably, which is conducive to reducing the vibration. So, our air jet loom can satisfy the requirement for weaving high-density textile.

| Breadth | 190-360cm, 70cm adjustable |

| Yarn Count | Staple fibre: Ne100-Ne5, filament: 40-500dtex |

| Weft Selection | Twin jet or quadruple jet, free weft selection |

| Shed Mechanism | Negative cam shed, 8 pieces of heald frame at most. |

| Positive cam shed, 10 pieces of heald frame at most. | |

| Dobby shed, 16 pieces of heald frame at most. | |

| Jacquard shed | |

| Selvage Weaving Mechanism | Rotary leno selvage |

| Temple | Top gear-ring temple |

| Weft Insertion | Single weft electronic weft accumulator, 2, 4 or 6 colors electronic weft accumulator |

| Stopping Device | Weft: photoelectric weft detecting device, double detectors |

| Warp: electric contact-type 6-line droppers | |

| Others: automatic stop motion for selvage or leno selvage | |

| The multifunction 4 color pause display shows the reason for stopping. | |

| Automation | Control: multi-function computer control system for parameter setting, control, monitoring, autognosis and manual operation |

| Broken picks seeking device for searching shed automatically | |

| Slow inching through frequency converter (forward and reverse rotation) | |

| Others: leading-out terminal of monitor |