Cast Resin Transformers

Dry type transformer

With the assistance of imported Germany’s Heydrich vacuum casting equipment, South China Electric develops and produces cast resin transformers (also known as dry type transformer). This kind of cast resin-encapsulated transformer adopts insulating coils, ensuring a stale performance and elegant looking. Our dry type resin transformer bears these following advantages: low-loss, high electric strength, high mechanical strength, heat resistance, flame retardant, anti-explosion and environmentally-friendly.

Important Advantages of Cores

1. A low magnetic flux density realizes vast decrease in core loss and noise.

2. A perfect aspect ratio contributes to reducing no-load loss and noise as well as preventing core from resonance.

3. All cores adopt high performance cold-rolled grain oriented silicon steel.

4. Our cores adopt 45°joints, step by step seam welding and non-porous structure.

5. A plate and clamp structure provides good machinery strength and even clamping force, effectively avoiding core loss and loud noise.

6. The finished core is covered epoxy resin painting, improving the core rigidity, cutting noise as well as avoiding rusting.

Windings

The high voltage winding has a continuous drop down disc with an aluminum strip conductor and double layer insulation. Windings are casted under vacuum with epoxy resin. Transient analysis test has been performed to verify the electrical stress distribution through the windings confirming the highest strength of our design.

The low voltage winding is made of copper or aluminum foil, and insulating foil pre-impregnated with resin. After the winding process, the coil is cured into an oven resulting in an extremely compact winding which can withstand the dynamic stresses produced by short-circuit.

Main Features of Windings

1. We adopt high quality foil material for windings, significantly upgrading its short circuit withstanding capacity.

2. In order to ensure the partial discharging less than 5pC, in addition to the F-rank packless epoxy resin, we introduce Heydrich pouring equipment and advanced techniques from Germany. After a strict vacuum drying, we carry out the vacuum pouring process.

3. We are committed to designing the best winding structure and insulation structure, considering the requirement for transformer insulating, temperature resistance and short circuit withstanding capacity.

Accessories

1. The enclosure is produced from good quality cold-rolled steel sheet and covered with epoxy electrostatic spraying. This process ensures a perfect match with the switch device and a good looking while installing. In addition, it has no effects on the lifespan.

2. We select high performance fans as cooling device, providing a strong guarantee of large air volume, low noise, low power consumption, long service life and maintenance-free. The efficient cooling device makes sure a normal operation of our cast resin distribution transformers.

3. We make use of stable performance temperature control device as a vital operating monitor for transformer. Not only that, we separately install this device on the enclosure, free it from the influence of power transformer and guaranteeing a stable performance and effective monitoring.

4. For the purpose of safe operation, our company can offer free locking device according to client’s actual demand. This device effectively increases the security capacity of our power transformers.

Tests

Voltage ration and connection group test

Load loss and short circuit impedance measurement

No-load loss measurement

Power frequency withstand voltage test

Induced over voltage test

Temperature rise test

Lightning impulse test

Partial discharge measurement

Other transformers like rectifier transformer are also available on request.

All of our products are designed and manufactured in compliance with international standards or client requirement. They have all passed routine test, type test and special test by national labs. Non-conforming products will be picked out.

Manufacturing Process

Traverse cutting

Traverse cutting Slitting

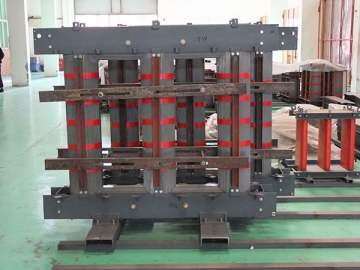

Slitting Cores are being laminated

Cores are being laminated

Laminated cores

Laminated cores High voltage winding of cast resin transformer

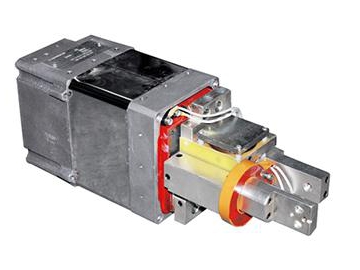

High voltage winding of cast resin transformer High voltage winding

High voltage winding

The cast resin transformer is being molded

The cast resin transformer is being molded The molded process is completed

The molded process is completed Germany’s Heydrich vacuum pouring device

Germany’s Heydrich vacuum pouring device

Finished windings

Finished windings The assembly process

The assembly process Our transformer is being installed with an enclosure

Our transformer is being installed with an enclosure