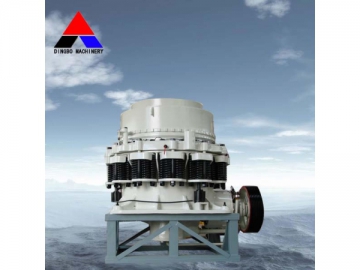

Cone Crusher

Our company has designed a modern high performance cone crusher on the basis of lamination crushing principle and the concept of the more crushing, the less wear. It has advantages of high swing frequency, optimized cavity and reasonable stroke. Due to the strong crushing ability and large output, this hydraulic cone crusher is widely used for crushing cobble and other medium hard materials. The crushed gravel features of good particle shape, that can meet the requirement of high quality construction.

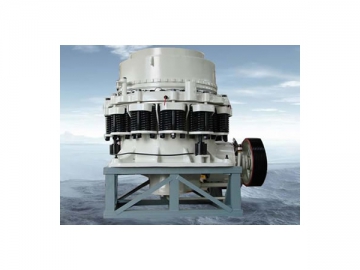

Working Principle

The cone crushing machine swings under the action of the eccentric sleeve, mantle and concave are used for pressing and grinding the materials. The material is subjected to multiple directions, and its texture will be crushed and polished, finally the material will be formed stable aggregate particles.

Application

Cone crushers are primarily used as secondary crushers to break down medium and soft minerals and rock materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum and graphite.

Features

1. High efficiency, this crushing equipment adopts optimized structure which has fixed main shaft and small spherical axle, it has higher crushing efficiency than that of ordinary cone crusher of 5-15%.

2. High output, our crusher combines the perfect designs of crushing stroke, crushing speed and crushing cavity.

3. High quality, our cone crusher uses laminated crushing way, it will have the breaking effect between particles, and the particle size is more uniform.

| Model | Moving Cone Diameter(mm) | Feed Opening (mm) | Max Feeding (mm) | Capacity (t/h) | Power (kw) | Eccentric Rotating Speed(r/min) | Weight (t) | Machine Size (mm) |

| 600 | 75 | 12-25 | 40 | 30 | 356 | 5 | 2234×1370×1675 | |

| 600 | 35 | 3-13 | 5-23 | 30 | 356 | 5.3 | 2234×1370×1675 | |

| 900 | 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692×1640×2350 | |

| 900 | 60 | 5-20 | 20-65 | 55 | 333 | 11.2 | 2692×1640×2350 | |

| 900 | 50 | 3-13 | 15-50 | 55 | 333 | 11.3 | 2692×1640×2350 | |

| 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790×1878×2844 | |

| 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 25 | 2790×1878×2844 | |

| 1200 | 50 | 3-15 | 18-105 | 110 | 300 | 25.3 | 2790×1878×2844 | |

| 1750 | 215 | 25-50 | 280-480 | 160 | 245 | 50.3 | 3910×2894×3809 | |

| 1750 | 185 | 10-30 | 115-320 | 160 | 245 | 50.3 | 3910×2894×3809 | |

| 1750 | 85 | 5-13 | 75-230 | 160 | 245 | 50.2 | 3910×2894×3809 | |

| 2200 | 300 | 30-60 | 490-750 | 260-280 | 220 | 80 | 4622×3302×4470 | |

| 2200 | 230 | 10-30 | 200-580 | 260-280 | 220 | 80 | 4622×3302×4470 | |

| 2200 | 100 | 5-15 | 120-340 | 260-280 | 220 | 81.4 | 4622×3302×4470 |

Note: all technical specification are based on relevant standards, additional requirements can be negotiated upon order placement.