Filter Press

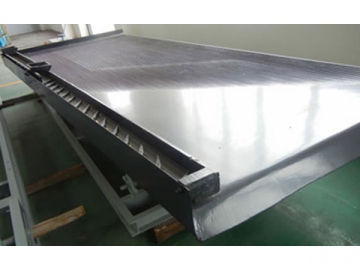

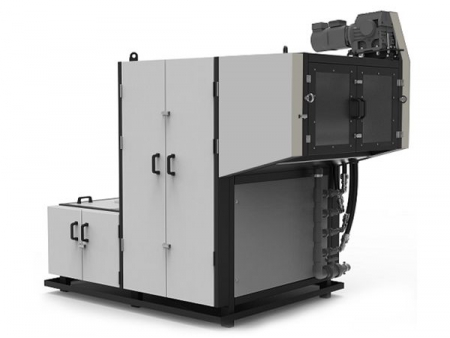

The DingBo filter press uses a TPE elastomer non-alkali fiberglass polypropylene material for maximum toughness while also using a flexible rubber diaphragm. These materials give the press filter a long service life with high resistance to corrosion as well as heat resistance up to 100℃ The frame of the mineral processing equipment features an optimized design with a high quality carbon steel compound.

The standing pressure force reaches 30 Mpa while filtration pressure can reach 1.2 Mpa. The automatic plate pull and discharge system uses a frequency conversion double motor with a tooth chain driven conveyor. The entire machine is PLC controlled for easy automatic operation.

Working Principle of the Filter Press:

The hydraulic system of the filter press opens the feed pump and pipe valves to automatically allow the slurry to movie into the filter press chamber. The first part of the filtration system removes large particles using a nylon cloth. When the removed particles fill up the machine, the machine will automatically shut down. After the solid particles are removed from the slurry, the mixture goes through a pressurized dewatering process where the powerful hydraulic press forces out all residual moisture.

Technical Parameters| Type | Filter Area (m2) | Pallet Size (mm) | Cake thickness (mm) | Filtering Volume (L) | Pallet Qty (pcs) | Filter Pressure (Mpa) | Power (Kw) | Weight (Kg) | Dimension (mm) |

| 80 | 1000 *1000 | 30 | 1219 | 46 | 0.6 | 4.0 | 5651 | 4500*1500*1400 | |

| 100 | 1505 | 57 | 6628 | 5150*1500*1400 | |||||

| 120 | 1816 | 69 | 7644 | 5870*1500*1400 | |||||

| 100 | 1250 *1250 | 1478 | 36 | 0.6 | 4.0 | 8307 | 4800*1850*1600 | ||

| 120 | 1765 | 43 | 9308 | 5270*1850*1600 | |||||

| 140 | 2094 | 51 | 10455 | 5770*1850*1600 | |||||

| 160 | 2381 | 58 | 11492 | 6350*1850*1600 | |||||

| 180 | 2669 | 65 | 12494 | 6810*1850*1600 | |||||

| 200 | 2965 | 72 | 13504 | 7200*1850*1600 | |||||

| 220 | 3285 | 80 | 14652 | 7800*1850*1600 | |||||

| 250 | 3737 | 91 | 16227 | 8500*1850*1600 |