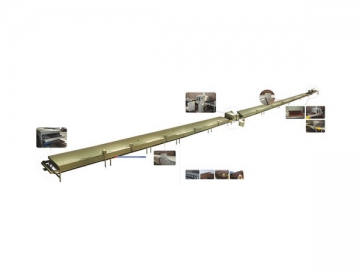

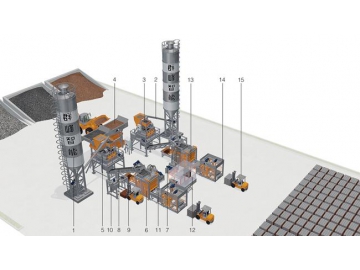

Stone Coated Steel Roof Tile Production Line

The stone coated sheet is formed using 0.4mm Al-Zn plating panels and color stones. The stone coated sheet is modern, environmentally friendly and features an aesthetically pleasing design.

We developed the stone coated production line based on our years of experience, continuous improvements and changing customer demands. It is known for its high performance, stability energy efficiency and easy operation.

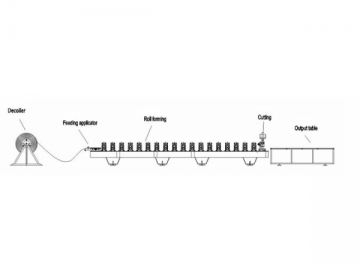

The production line has 5 main parts:

1. Auto bottom glue spraying section

2. Automatic stone coating section

3. The first time drying section

4. Auto face glue spraying section

5. The second time drying section

Detailed Introduction:

| NO. 1 Auto bottom glue spraying section | |

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW excitation motor or frequency speed regulation (as per customers’ requirements ) |

| Automatic pressure spray tank | 1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

| Automatic glue machine motor | Servo motor ; Power: 750w ; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set ; Power: 200w |

| Damp proof lamp | 1 pc ; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set ; Power: 7.5kw |

| Dust control of axial flow fan | 1 set ; Power: 200w |

| Agitator | 1 set ; Power: 1.5kw |

| NO. 2 Auto stone coated section | |

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set ; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

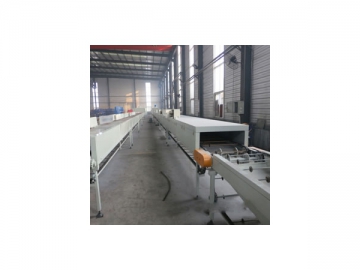

| NO. 3 The first time drying section | |

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with rock wool |

| Automatic temperature controller | 4 sets ; Range: 0°~160° |

| Infrared heating tube | 30pcs ; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set ; Power: 200w |

| NO. 4 Auto face glue spraying section | |

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pc ; Power:100w |

| Automatic pressure spray tank | 1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set ; Power: 200w |

| Automatic glue machine motor | Servo motor ; Power: 750w |

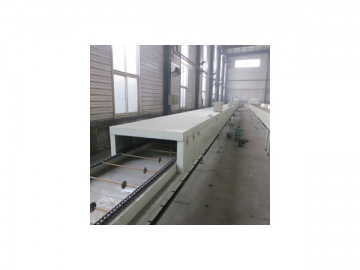

| NO. 5 The second time drying section | |

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets ; Range: 0°~160° |

| Infrared heating tube | 30pcs ; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set ; Power: 200w |

This line is 65.5M long, therefore the minmum workshop length must be 70 meters. However, we can also design the machine to be used in two stations, which allows for a workshop space of 35 meters in length.

To use this machine, a 2 x 3 air compression room is needed as well.

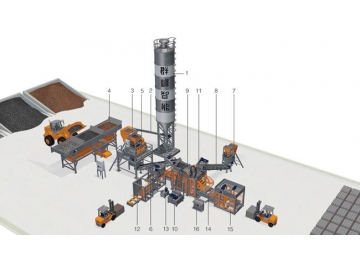

| PLACE | QTY. |

| Panel loading | one |

| Bottom spraying | one |

| Stone coating | one |

| Fill stone | one(Do not need ) |

| Face glue | one |

| Bottom glue mixing | one(Not necessary) |

| Finish goods receiving | one |