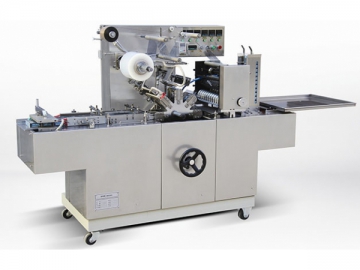

Cellophane Overwrapping Machine, BTB-300C

Product Introduction

Developed using the concept for the BTB-300B cellophane overwrapping machine, the BTB-300C has an added color mark calibration system, comprised of a Panasonic servo motor, Siemens controlling modules and a PLC touch screen. The overwrapping machine features a stable and easy operation, and runs quickly. This packaging machine is primarily used to automatically wrap various single piece or single slice articles in a printed film, such as handkerchiefs, removable self-stick notes, notepads, playing cards, soap and other products.

Automatic Grade: Automatic

Driven Type: Electric

Application: food, cosmetics, stationary, hardware, daily use products, pharmaceutical products

- single product & bulk products

| Packing Material | BOPP film and gold tear tape |

| Packing Speed | 30 ~ 50 packs/min |

| Packing Size | (L)240 x (W)120 x (H)60mm |

| Electric Supply & Power | 220V 50Hz 5kw |

| Weight | 600kg |

Features:

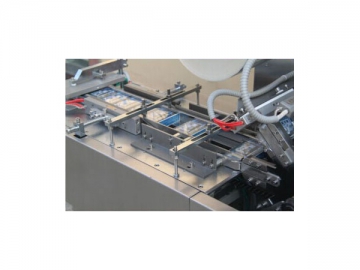

1. There is no need to regulate the height of the two work tops on the machine when the mold needs to be replaced. There is also no need to assemble or dismantle the material discharge chains or discharge hopper, which reduces the mold replacement time from 4 hours to 30 minutes.

2. A new double safeguard mechanism is used, preventing damage to spare parts in the event of incorrect wrapping machine operation.

3. A unilateral hand swing device prevents machine vibration, and the prevention of hand wheel rotation during machine operation ensures the safety of the machine operator.

4. A new double rotary film cutter ensures there is no need to mill a blade after multiple years of machine operation. This overcomes obstacles posed by a traditional stationary single rotary film cutting knife that wore down faster.

| No. | Item | Qty | Brand |

| 1 | Touch screen | 1 | Weinview (Taiwan) |

| 2 | PLC | 1 | Siemens(Germany) |

| 3 | Temperature controller | 2 | Siemens(Germany) |

| 4 | Inverter | 1 | Siemens(Germany) |

| 5 | Servo motor driver | 1 | Panasonic (Japan) |

| 6 | servo motor | 1 | Panasonic (Japan) |

| 7 | auxiliary relay | 4 | Omron (Japan) |