Large Bottle Filling Machine (3-5 Gallon)

- Main machine

- Main machine

- Side of main machine

- Detailed drawing of side of main machine

- Detailed drawing of side of main machine

- Rotary filling machine

- Linear filling machine

- Capping machine

EcoPura's 5 Gallon Turnkey bottling plant design is based on the following standards:

Food safety: Discover how our hygienic food safety solutions protect both your beverage and end consumers.

Product integrity: EcoPura's solutions and technical expertise will ensure your drink passes through the supply chain intact.

Line flexibility: Meeting modern demands requires a new level of production line flexibility.

Production efficiency: Our production line ranges help you maximize output and uptime while keeping costs and environmental impact down.

Consumption reduction: Users can increase production and still use fewer resources.

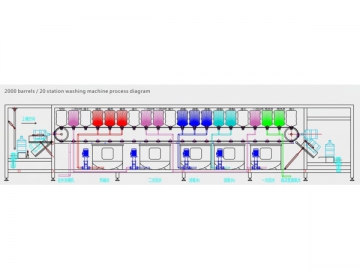

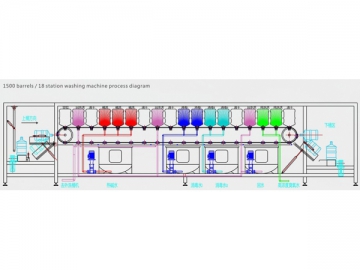

Main configuration of EcoPura's 5 Gallon bottling solutions: Up to 2500BPH bottling plant

Control System PLC: Siemens PLC, Motor: Italian / MOTOVRIO

Machine's Frame: AISI304 Material thickness: 2mm-5mm

Board Material: AISI304 Material thickness: 2mm

Patented design for the key process rinsing-filling-capping machine

Multistage washing: detergent washing -- hot-alkaline washing -- clean washing -- ozone water washing

Each washing part is controlled by separate mobile S.S316 tank & S.S304 piping & valves.

Rinsing performance depends on rinsing pressure and flow, time, nozzle, rinsing process and equipment stability

EcoPura's Rinsing Pressure & Flow:

Uses vertical high pressure pumps, frequency conversion control and new motors for mechanical control. This leads to a rinsing pressure of 3-4KG, and a nozzle flow of about 1T/H. Frequency conversion technology is used to adjust rinsing pressure and flow, and the patented mechanical design ensures the spraying bar ascends into gallon bottles. The liquid filling machine's motor driven spray bar can move up and down with a wash pressure of 3-4kgs for rinsing every corner in the gallon bottles. The large bottle filling machine's performance is excellent, and guarantees 100% clean and healthy bottles.

EcoPura's Rinsing Time:

1. Controlled by PLC, or set on touch screen programmer

2. Hot alkaline washing 35-50 seconds; heating at a constant temperature of 55-70° C

3. Sterilization time: 65-80 seconds

EcoPura's Rinsing Nozzle

3 types of rinsing combination designs are available for bottle bottom, body and neck place washing to make sure bottles are 100% clean inside.

1. Normal spraying nozzle

2. Spiral nozzle

3. Rotating spherical nozzle

EcoPura's Washing Process:

1. Between each different washing processes, users must drain and clean the bottle filling machine, before insert ing the baffle wall to prevent water mixing with chemicals, allowing users to save water and chemical solutions.

2. Chemical washing & Ozone water washing equipped the device to soak and clean bottle mouth,

EcoPura's Equipment stability

Clients need machines that operate in a stable manner for a better performance.

1. A mechanical device pushes the bottles for feeding

2. Barrels on a positioning device

3. Vertical loading

4. Bottle outlet pushing device

EcoPura's Filling Part

Quantitative filling with micro adjustable valve; globe valve

- Automatic De-capper

- Automatic rotary style bottle outside brusher rinsing

- Automatic bottle feeder / loader

- Automatic caps sterilizer

and feeder - Automatic capsules shrinking with light checking

- Automatic lifting &

bagging - Automatic pallet stacker