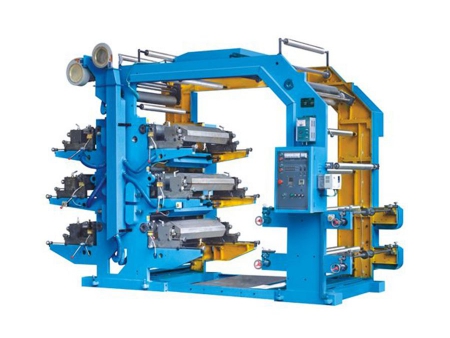

4/6 Color Flexographic Printing Machine

Request a Quote

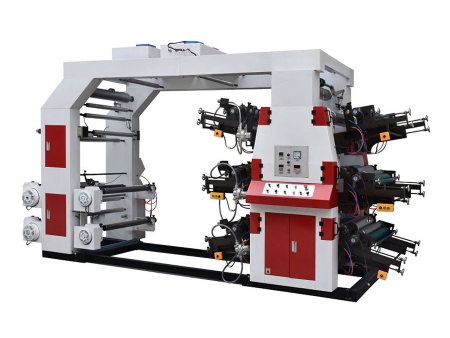

CI Flexo Press for Film Printing

Six-Color Flexography Printing Machine

Technical Parameters

| Model | YT-6600 | YT-6800 | YT-61000 | YT-61200 |

| Max. printing width (mm) | 560 | 760 | 960 | 1160 |

| Max. web width (mm) | 600 | 800 | 1000 | 1200 |

| Max. printing speed (m/min) | 50 | 50 | 50 | 50 |

| Max. mechanical speed (m/min) | 60 | 60 | 60 | 60 |

| Max. diameter of material (mm) | ф450 | ф450 | ф450 | ф450 |

| Inner diameter of roll (mm) | ф76 | ф76 | ф76 | ф76 |

| Repeated length (mm) | 191-1200 | 191-1200 | 191-1200 | 191-1200 |

| Accuracy (mm) | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

| Thickness of flexible plate (two-sided adhesive paper included, mm) | 2.38 | 2.38 | 2.38 | 2.38 |

| Power of heater (kW) | 8 | 9 | 10 | 12 |

| Total power (kW) | 11.5 | 15 | 18.5 | 22 |

| Weight (kg) | 3500 | 3500 | 4000 | 4500 |

| Dimensions(mm) | L4300×W1700× H2500 | L4300×W1900× H2500 | L4300×W2100× H2500 | L4300×W2300× H2500 |

Four-Color Flexography Printing Machine

Technical Parameters

| Model | YT-4600 | YT-4800 | YT-41000 | YT-41200 |

| Max. effective printing width (mm) | 560 | 760 | 960 | 1160 |

| Max. web width (mm) | 600 | 800 | 1000 | 1200 |

| Max. printing speed (m.min) | 50 | 50 | 50 | 50 |

| Max. mechanical speed (m/min) | 60 | 60 | 60 | 60 |

| Max. diameter of roll material (mm) | ф450 | ф450 | ф450 | ф450 |

| Roll material inner diameter (mm) | ф76 | ф76 | ф76 | ф76 |

| Repeated length (mm) | 191-1200 | 191-1200 | 191-1200 | 191-1200 |

| Accuracy (mm) | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

| Thickness of flexible plate (two-sided adhesive paper included, mm) | 2.38 | 2.38 | 2.38 | 2.38 |

| Power of heater (kW) | 8 | 9 | 10 | 12 |

| Total power (kW) | 11.5 | 15 | 18.5 | 22 |

| Weight (kg) | 2500 | 3000 | 3500 | 4000 |

| Dimensions(mm) | L4300×W1700× H2500 | L4300×W1900× H2500 | L4300×W2100× H2500 | L4300×W2300× H2500 |

Main Parts

- Unwinder 1. Automatic tension control, aided by a 2.5 kg magnetic brake, eliminates worker error and minimizes risk.

2. Motor type EPC is capable of producing film edges that are even and consistent.

3. The utilization of air shafts can significantly enhance productivity.

4. The Machine will automatically shut off when materials are depleted. - Rewinder Automatic tension control with air shaft

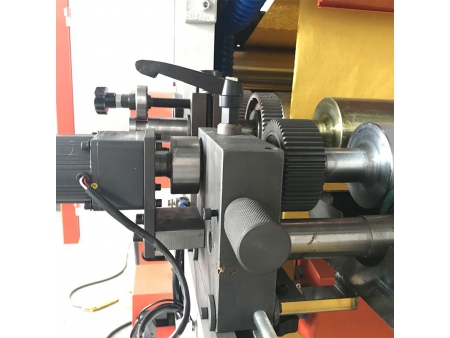

- Driving System 1. Main Motor: Meets CE standards for an anticipated life of 10 years.

2. Driving by gear with a longer lifespan. Adding lubrication oil in order to ensure smoother running and a reduced level of noise.

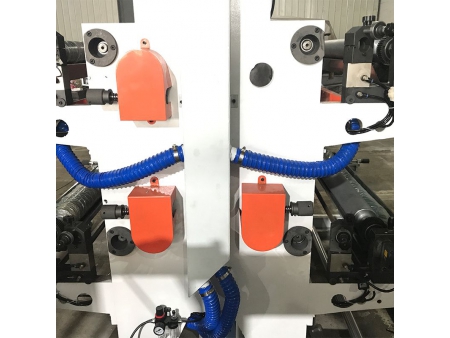

3. The whole printing driving system is composed of a singular straight gear that’s essential for the operation of all machines. Lubrication oil needed. - Printing System 1. Our roller is of the highest quality and is resistant to corrosion from inks.

2. Strong adjust bar.

3. An Ink Motor that operates independently allows the ink roller to keep running while the machine is not in use, meaning that the ink won't dry out easily.

4. The air lifting system for plate roller provides an effortless experience.

5. Printing color match adjusting parts

6. The product length is counted in meters. - Drying System 1. A large oven situated above the machine, capable of drying the printed images.

2. Two separate ovens, one for each color, will enable the ink to dry faster. - Electric Parts Delta inverter and automatic tension.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos