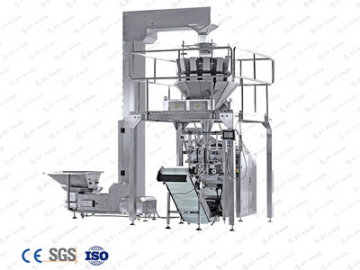

Powder Pouch Filling Sealing Machine

Packing Sample Pictures

| Model | HP-6PC | HP-8PC | HP-10PC |

| Mechanical workstation | 6 | 8 | 10 |

| Packaging materials | Laminated film, PE, PP, etc. | Laminated film, PE, PP, etc. | Laminated film, PE, PP, etc. |

| Pouch types | Stand up (with or without zipper), flat bag (3/4 side seal bag, hand bag, zippered bag), paper bag, etc. | Stand up (with or without zipper), flat bag (3/4 side seal bag, hand bag, zippered bag), paper bag, etc. | Stand up (with or without zipper), flat bag (3/4 side seal bag, hand bag, zippered bag), paper bag, etc. |

| Pouch size | W: 100-300mm L: 100-400mm | W: 100-240mm L: 100-300mm | W: 100-200mm L: 100-300mm |

| Packaging speed | 30-60 bags/min (depending on film and material weight) | 30-60 bags/min (depending on film and material weight) | 50-80 bags/min (depending on film and material weight) |

| Machine weight | 1000KG | 1200KG | 1400KG |

| Power supply | Three-phase 380V 50HZ/60HZ | Three-phase 380V 50HZ/60HZ | Three-phase 380V 50HZ/60HZ |

| Total power | 2KW | 2KW | 3.5KW |

| Compressed air consumption | 0.6m³/min (or customized) | 0.6m³/min (or customized) | 0.6m³/min (or customized) |

| Dimensions | 1550 (L)×1350 (W) ×1400(H) mm | 1550 (L)×1350 (W)×1400 (H) mm | 2145 (L) ×1750 (W) ×1550 (H) mm |

| | | |

Main Features

1. The powder pouch filling sealing machine replaces traditional manual packaging, realizes mass production and greatly decreases cost.

2. The automatic pouch sealing machine is compliant with food hygiene standards and material contacting parts all apply hygienic materials to ensure a high food safety level.

3. Pre-made pouches used have nice pattern and good seal quality.

4. Applicable packaging materials include laminated film, single-layer PE, PP film, paper, etc.

5. The pouch bagging machine is suitable for packaging powder products, such as milk powder, tea powder, coffee, etc.

6. For electric control system, the doy pack filling and sealing machine makes use of Mitsubishi PLC, color touchscreen and human-computer interface. The powder pouch filling sealing machine is convenient to operate. The variable frequency motor allows flexible speed which can be adjusted according to actual manufacture demands.

7. Automatic inspecting system detects many process related procedures and parameters, such as air pressure, temperature, bag feeding, filling, sealing quality, machine state and coding. By doing so, packaging material and raw material can be saved.