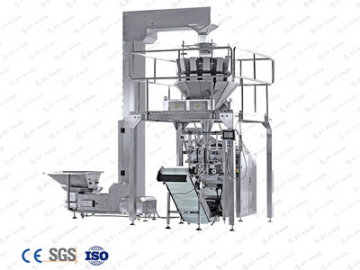

Vertical Powder Filling Sealing Machine

(0.2-5kg)

Packing Sample Pictures

| Model | HDP-400 | HDP-500 | HDP-620 |

| Max. film width | 400mm | 500mm | 620mm |

| Bag width | 60-190mm | 80-240mm | 110-300mm |

| Bag length | 50-230mm | 50-230mm | 50-380mm |

| Packing speed | Max.100bpm | Max.100bpm | Max.100bpm |

| Power supply | 220V,50Hz,3.5Kw | 220V,50Hz,4Kw | 220V,50Hz,4Kw |

| Air consumption | 0.2³/Min,0.6Mpa | 0.2³/Min,0.6Mpa | 0.2³/Min,0.6Mpa |

| Dimensions | 1300X960X1150mm | 1550X1160X1480mm | 1600X1260X1680mm |

| | | |

| No. | Name | Model | Manufacturer |

| 1 | Color touch screen | MT6056IV | Weilun, Taiwan |

| 2 | PLC | FX3G-60MT | Mitsubishi, Japan |

| 3 | Servo motor | DDDT3530053 750w | Panasonic, Japan |

| 4 | Cylinder and pneumatic components | AirTAC | AirTAC |

| 5 | Magnetic valve | Mindman | Mindman,Taiwan |

| 6 | Triplet | AirTAC | AirTAC |

| 7 | Photoelectric sensor | Shike, Germany | |

| 8 | Switching-mode power supply | ABL 2REM24065 150W/24V (DC) | DELTA ,Taiwan |

| 9 | Solid-state relay | JSR-1D40Z2 | OTOSOL, Korea |

| 10 | Intermediate relay | DRM27OO24L | WEIDMULLER, Germany |

| 11 | Temperature controller module | DELTA | DELTA ,Taiwan |

| 12 | Proximity switch | SN04-N | RIKO, Taiwan |

| 13 | Film transfer motor | YN90-40W/JB10G12 | V.T.V |

| 14 | Switches and buttons | Double control switch B22-WP26-510-804 | BENLEE, China |

| Green button B22-GA11-510-422 | |||

| Red emergency button B22-RR21-501-000 |

Features

1. The PLC controller has a human machine interface and is easy to operate.

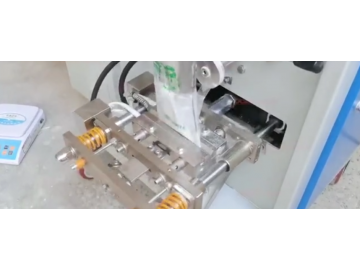

2. Sealing and film drawing are controlled by a dual-servo system, with high precision.

3. Both coding system and film feeding system works synchronously with the vertical packaging machine.

4. The packaging size can be changed easily and quickly.

5. Detecting device will give an alarm for powder leakage.

6. An optoelectronic sensor is used for automatic tracking.

7. The stainless steel frame guarantees lifespan and hygiene.

8. Laminated film and mono-film are available.

Optional Configurations

This vertical powder filling sealing machine has many optional configurations, including air filling device, nitrogen filling device, gas exhausting device, hole punch, material vibrating device, protection system, tear notch device, bag corner device, anti-leakage device, bag support device, PE sealing system, vacuum device, electrostatic eliminating device, four-side folding device, film correcting device.