UV Curing

Request a Quote

Function

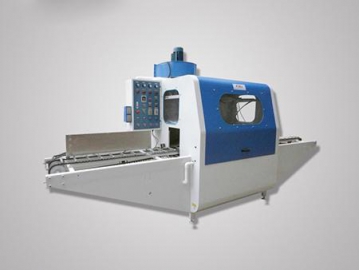

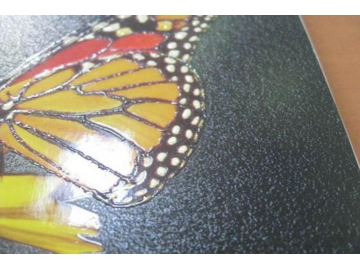

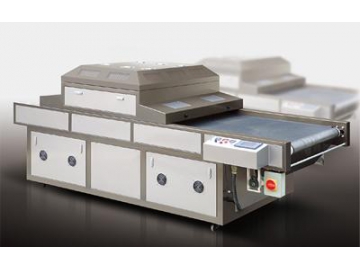

- The UV curing machine is designed to cure UV coatings. Due to UV coating’s high sensitivity to the UV light, it will cure immediately dry once contacting the UV light. The UV curing machine is suitable for filling up paint (the unsmooth part) or curing UV coating, such as transparent base coat, colored base coat and top coat. The fast speed of UV drying allows to shorten the production cycle, improve the production efficiency and apply to the flow line production.

- A custom UV curing solution is available in XMF. The number and width of lamps can be adjusted based on your UV coating type, the sides of the substrate that need to be processed and the size of the substrate.

Application

UV curing machine is widely used for curing UV coating on substrate of wood, synthetic board, plastic, glass, metal and etc.

Features

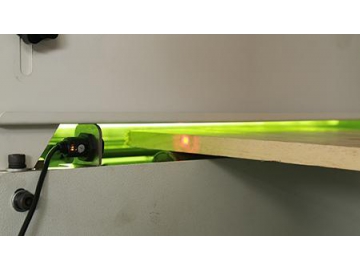

- The long-time irradiation of UV light results in a high temperature in light box, which will shorten the machine service life. Therefore, XMF UV curing equipment adopts a spilt type UV light box—each UV lamp is equipped with an independent light box and an independent cooling system. Compared to the integrated light box, the split type features faster cooling speed and achieves lower box temperature and longer working life.

- Each UV lamp is independently controlled. The intensity of light can be regulated according to the characteristics of UV coating and two modes are optional—lowlight or highlight.

- As the light energy will gradually attenuate as the long-time usage, a height adjustment design is added for each lamp of the curing machine. When an UV lamp has no enough energy, you can reduce the height of this lamp to guarantee the curing performance and extend its service life.

Working principle

The pattern which customer needs are engraved on the pattern roller. After adjusting the distance between the pattern roller and the substrate, due to the large pressure of the pattern roller, it will emboss a stereo grain on the substrate. A built-in heating device can heat the pattern roller to 400 ℃ and the heated embossing pattern is more fixed and unchangeable.

Optional model

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos