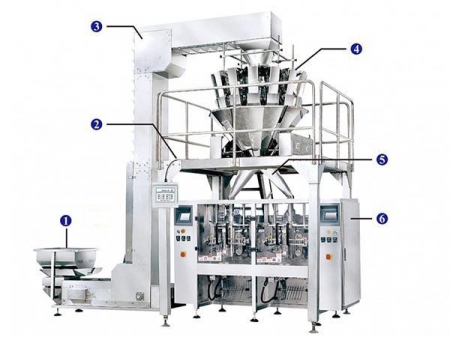

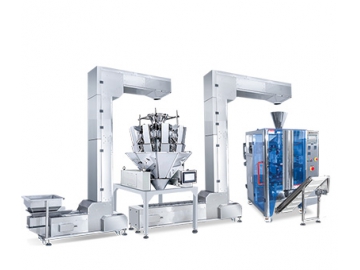

JW-LCX2 Twin Tube Vertical Bagging System,with 14 heads weigher, double discharge outlet

- Vibratory feeder

- Working platform

- Z-shaped elevating conveyor

- 14 heads weigher

- Double discharge outlet

- Twin bagger

The JW-LCX2 twin tube vertical bagging system with a 14 heads weigher is composed of the vibratory feeder, working platform, Z-shaped elevating conveyor, 14 heads weigher and twin bagger to automatically complete the entire feeding, weighing, bag forming and filling, bag sealing, label printing and discharging process.

The twin bagger has a maximum packaging speed of 120 packs per minute, making it ideal for clients with requirements for a large production output and a higher production efficiency.

Applicable bag materials: Composite film with thickness between 0.03-0.15mm, single layer PE film, paper film and more

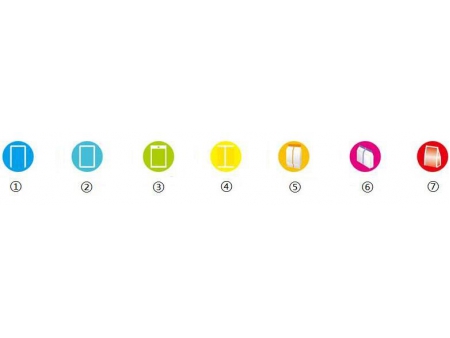

Applicable bag types

② 4 side seal pouches

③ Flat bags

④ Back sealed bag

⑥ Gusset bags

⑦ Quad-seal gusseted bags

| Packaging speed (Pack/Min) | 120P/M |

| Film width | 160-420mm |

| Single weighing range | 100-3000g |

| Film thickness | 0.04mm~0.15mm |

| Twin bagger power | 3.4KW |

| Twin bagger voltage | 220V |

| Multihead weigher power | 1500W |

| Multihead weigher voltage | 220V |

Note: The provided parameters are for reference only, and we will manufacture custom -twin tube vertical bagging system according to your specific production types, weighing range, factory area and output.

- Check weigher

- Metal Detectors

- Combined metal detector and check weigher

- Thermal Transfer Overprinter

- Count verification machine

- Conveyor equipment

- Accessories