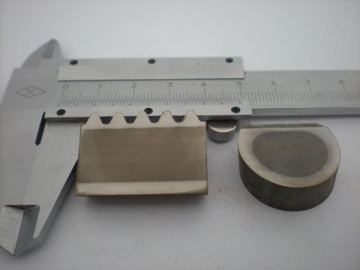

Samples of Hardened Parts

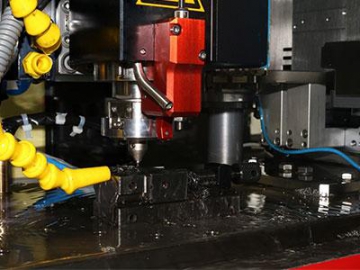

If you are hardening parts that have complex profiles, then our induction quenching machine will be your wise choice. We will provide you with a variety of quenching methods and technical solutions, to better save your efforts and increase your productivity.

The followings are some brief introductions to some typical parts

1. Thin walled partsSuch parts are inclined to be through hardened, which will consequently cause crack. Thin walled parts generally requires a relatively high hardness to increase wear resistance. We have several options to achieve the process properly without over hardening.

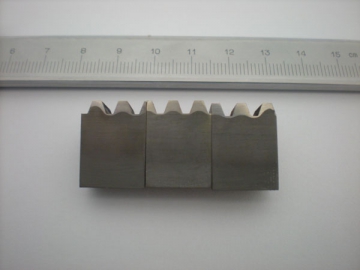

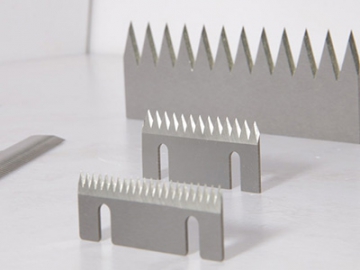

2. GearsIt is not easy for small module gears to gain a profiling hardened layer. Conversely, the teeth tips are easy to be through hardened. Thus, the deformation of parts will be particularly inclined and increase the subsequent processing time and efforts. The profiling quenching process that we designed for these small module gears, will spare your efforts.

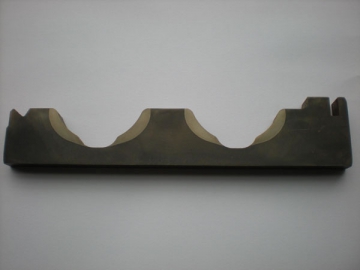

3. RacksDue to the working principle, the teeth of steering rack requires high hardness, and the center requires sufficient resilience. So we use the conductive quenching to meet both of the requirements. You will get a profiling hardened layer, as well as hardened teeth and resilient center.

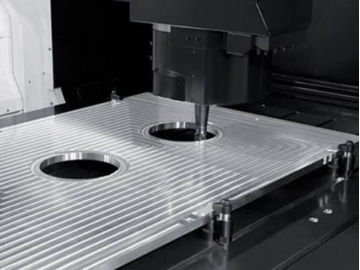

4. Guide railsThe contact surface between rail and slide usually requires quenching. But because the rail is very long, the rail may easily bend after quenching. So we take a series of measures to prevent deformation, and the results have been well verified at customers' sides.

5. Motor shaftsMotor shaft parts generally contain splines and gears, which need quenching process. We have a variety of process methods that can improve the efficiency and stability of the production.

6. Elevator wheelsElevator wheel parts require good wear resistance, but are generally prone to over-quenching and inconsistent hardening. The productivity is also low. Engineering-proved new technologies are applied to solve the above problems, with very stable production.

7. Control valve sleevesThe control valve sleeve is also a part of automotive steering systems. The conventional heat treatment will generate a relatively large degree of deformation, increase the grinding process time, and reduce productivity. We adopt new technology to get the deformation well controlled, greatly improving production efficiency.

8. Slewing bearingsSlewing bearings are generally used for wind power generation equipment, construction equipment, etc. Our special equipment addresses a variety of requests.

9. Hub bearingsHub bearings are commonly used in the car. These parts may seem simple, but because it is used on the car, it must have relatively high safety factor. We specially designed and manufactured dedicated automatic induction machines that have good processing accuracy to ensure the quenching quality.

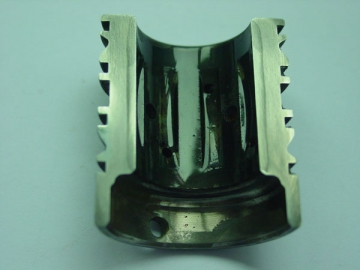

10. C.V. jointsCV joints are very important automotive parts. They need to be hardened, but easily get over-hardened because of the thin wall. We have mature heat treatment process, and have provided sets of equipment to a number of customers.

11. Ball jointBall joints are common auto parts. The surface needs heat treatment. We have special machine tools for the processing of such parts, to ensure stable quality and efficient production.

12. CrankshaftsCrankshafts are typical parts in automotive, motorcycle fields. Due to the structural characteristics, namely the eccentricity and crank portion, crankshafts are not easy to be quenched. So we have the quenching power distribution technology ready for the processing. This method is very sophisticated to ensure the stability and consistency of crankshaft hardening.

13. Pump shaftsPump shafts are commonly used. We have dedicated automatic equipment for the processing, and advanced heat treatment process to ensure the quality and stability. The equipment is well-received among many users.

14. CamshaftsCamshafts are very typical parts in heat treatment. Conventionalheat treatment is generally difficult to achieve a uniform hardened layer, which we call profiling. So we use ordinary ring inductor and advanced technologies to achieve a profiling hardened layer, which reduces production costs and optimizes production efficiency.

15. Micro shaftsThe very typical characteristic of such parts is as the name suggests—the shafts are too small for heat treatment. But we still have dedicated equipment and advanced heat treatment technology to process them.

16. Pin bushesTypically, such parts generally need both inner and outer surfaces to go through heat treatment, which is difficult to achieve using conventional heat treatment methods. We have special equipment and sophisticated heat treatment process to make the hardening possible. We can guarantee stable quality and high yields.

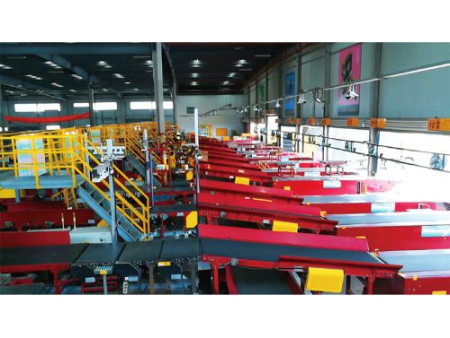

17. Guide wheelsGuide wheels are typical engineering machinery parts, widely used in urban construction. We have sets of special equipment and advanced heat treatment process to realize the in-line production of guide wheels, greatly improving production efficiency.

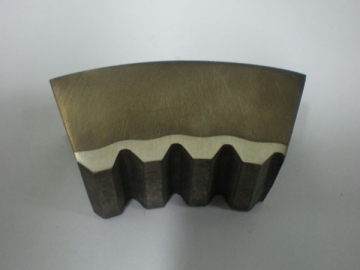

18. SprocketsSprockets are typically used in construction machinery. It is not easy to achieve profiling quenching on them. But we have mature technology and special equipment for the processing, improving the quality of heat treatment and increasing productivity.