Servo System for Six-axis Articulated Robot

Foreword

Increases in human labour cost have put an added strain on machine tool industries. Sure, a machine tool can operate 24 hours a day without stop. However, machine tool operators can not follow in the same pattern. The use of articulated robot allows the machine tool to operate continuously and safely when no one is around.

Model Selection

| Servo Drive | Servo Motor | |

| Axis 1 | P-H15BT3 | 130SD04830P(S) |

| Axis 2 | P-H15BT3 | 130SD04830PZ(S) |

| Axis 3 | P-H08BT3 | 80SD02430PZ(S) |

| Axis 4 | P-H02BT2 | 60SD00630P(S) |

| Axis 5 | P-H02BT2 | 60SD00630P(S) |

| Axis 6 | P-H02BT2 | 60SD00630P(S) |

Servo System Commissioning

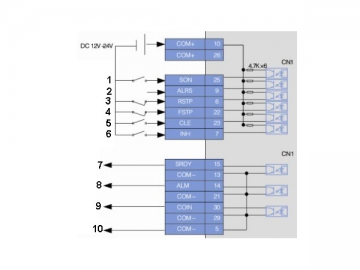

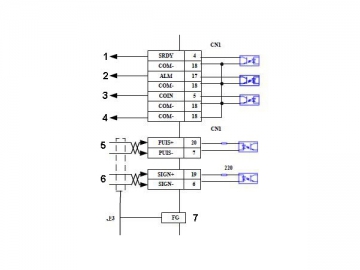

1. Wiring

| Servo drive CN2 | RS-485 communications | controller | |

| pulse ( ) | |||

| pulse (-) | |||

| orientation ( ) | |||

| orientation (-) | |||

| A | |||

| A- | |||

| B | |||

| B- | |||

| alarm output | |||

| 0 | |||

| shielded cable | |||

2. Parameter Setting

The servo system, coupled with the upper computer, forms a complete, closed-loop control system which ensures accuracy in positioning of the robotic arm. During machining operations, the robotic arm needs to be quick in response with smooth start-up and stop. In speed estimation mode, the servo system is capable of precisely calculating the motor load, and improves the servo repsonse speed by 30% accordingly while delivering low noise.

| Parameter Code | Parameters | Axis 1 to Axis 3 | Axis 4 to Axis 6 |

| PA4 | Control mode: position control | 1 | 1 |

| PA5 | Speed proportional-integral controller | 80 | 120 |

| PA9 | Position proportional-integral controller | 80 | 100 |

| PA12 | Gear ratio numerator | 8192 | 8192 |

| PA13 | Gear ratio denominator | 375 | 375 |

| PA32 | Speed estimation function enabled | 1 | 1 |

| PA48 | Braking delay time when power is on: s | 100 | 100 |

| PA49 | Braking delay time during outage: ms | 200 | 200 |

The succesful use of our servo system on the 6-axis robot greatly improves manufacturing efficiency. The outstanding stability and high cost to perofrmance ratio makes the servo system more competitive in robotic motor control industries.