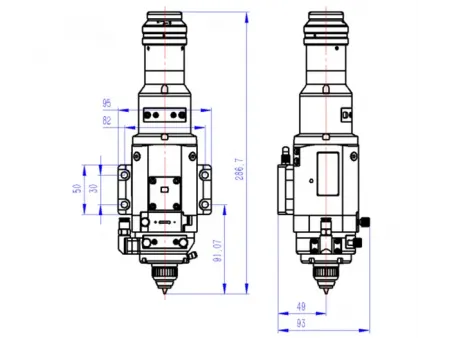

2kW Micro Laser Cutting Head

LC119

Manual focus laser cutting head for performing ultra-fine cuts with high precision

LC119

Manual focus laser cutting head for performing ultra-fine cuts with high precision

Our 2 kW manual-focus micro heads use a rotary focus dial with a 1 mm minimum adjustment to set focus precisely, so kerfs stay narrow, and heat input stays low. These laser processing heads can fit laser cutting machines via a QBH interface and cut stainless steel, titanium/Nitinol, aluminum, and copper with a clean finish. They can be used to cut products such as instrument springs, micro brackets, sensor frames, and other small medical parts that require repeatable dimensions.

| Type | Manual Focus Micro Laser Cutting Head |

| Model | LC119 |

| Interface Type | QBH |

| Wavelength | 1080±10nm |

| Rated Power | ≤2kW |

| Focal Length | 75mm |

| Collimation Length | 100mm/125mm |

| Focusing Range | -3mm~ 3mm |

| Centering Adjustment Range | ±1mm |

| Auxiliary Gas Pressure | ≤1.5MPa |

| Weight | 2kg |

The manual-focus micro laser cutting heads we offer are suitable for precision medical-device manufacturing, especially for small, complex parts in tight assemblies. They support fine-feature machining on multiple metals, including stainless steel, titanium alloys, and nickel-titanium (Nitinol), while keeping edges clean and dimensions consistent.

- Flexible notched tubes (Medical use)

Works at a short stand-off for tight spaces and compact setups, expanding where the laser head can be used.

Lets you set focus precisely on very small features and controlled cut depth.

A rotary mechanism shifts the focal position precisely and locks in place. That stability keeps cut depth and edge quality consistent across a batch.

The focus unit is isolated to maintain beam concentricity (no optical drift), which supports accuracy and stability.

The protective window sits in a slide-out module, so you can swap it without stripping the head. Maintenance is faster, optics stay clean, and downtime drops.