Self-Drilling Anchor System

The self-drilling anchor system is an advanced anchoring solution on the market. It provides stability in soil or rock formations and is a key anchoring system in rock reinforcement projects, ensuring safety and structural rigidity.

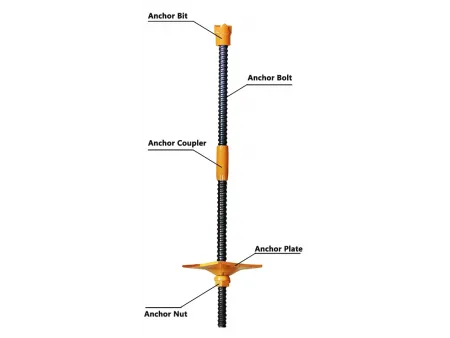

Our self-drilling anchor is equipped with different parts. At the drilling end is the anchor bit, which creates the borehole while facilitating grouting. The anchor bolt, serves as the primary support structure. The anchor coupler extends the bolt's length when necessary, while the anchor plate distributes surface loads to ensure stability. Finally, the anchor nut locks the system securely in place, completing the setup for optimal performance.

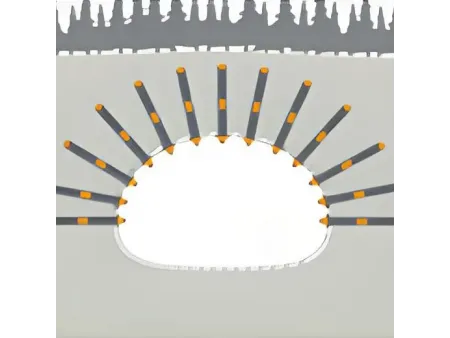

This SDA is ideal for soil nailing, tunneling, micropiling, and other engineering projects requiring reliable and efficient rock reinforcement.

Our self-drilling anchor system has features that make it efficient and reliable. The structure is designed to do all three steps of installation—drilling, grouting and anchoring—in just one step, making installation fast and easy. Additionally, the drilling process is quieter. The self-drilling anchor system eliminates the need for separate the anchor bars installation and removal because the drill bit remains underground, functioning as a spacer.

We offer a range of drill bits to work with different types of soil. The hollow anchor bolts allow air or water to flow through during drilling, filling any spaces with grout, and high-pressure grouting in the annular space. We also provide a variety of high-quality grouting materials and mixers, along with flexible-length anchor coupler for different project needs.

Our drilling system is designed to work well with compact drilling rigs and in small spaces. It also has enhanced corrosion protection and is made according to strict quality standards.

The self-drilling anchor system is a versatile solution with applications across various industries and projects. It is widely used in:

-

- Bar Size:

- Ultimate Load (kN): 200

- Yield Load (kN): 150

-

- Bar Size:

- Ultimate Load (kN): 280, 360

- Yield Load (kN): 230, 280

-

- Bar Size:

- Ultimate Load (kN): 500

- Yield Load (kN): 400

-

- Bar Size:

- Ultimate Load (kN): 550, 800

- Yield Load (kN): 450, 630

-

- Bar Size:

- Ultimate Load (kN): 1600, 1900

- Yield Load (kN): 1200, 1500

-

- Bar Size:

- Ultimate Load (kN): 320

- Yield Load (kN): 260

-

- Bar Size:

- Ultimate Load (kN): 660, 540

- Yield Load (kN): 525, 425

-

- Bar Size:

- Ultimate Load (kN): 930

- Yield Load (kN): 730

-

- Bar Size:

- Ultimate Load (kN): 1035, 1160, 1600

- Yield Load (kN): 830, 970, 1270

-

- Bar Size:

- Ultimate Load (kN): 2270, 3660

- Yield Load (kN): 1800, 2670

- Hollow Anchor Bar (Anchor Bolt)

The anchor bolt is the main part of the system. It transfers loads from the surrounding rock or soil to the anchoring system's load-bearing elements.

- Anchor Coupler (Anchor Coupler)

The anchor coupler connects two anchor bolts, allowing the system's length to be extended to meet project-specific requirements.

- Anchor Drill Bit

The drill bit is designed to create boreholes in rock or soil. It remains in place after installation, ensuring seamless anchoring through the drilled hole.

- Anchor Plate

Attached to the end of the anchor bar, the anchor plate distributes the applied loads evenly across the surrounding rock or soil, providing additional stability.

- Anchor Nut

The anchor nut secures the anchor plate to the anchor bar, locking the system in place for reliable load transfer.

- Anchor Centralizer / Spacer

The self-drilling anchor centralizer is a tool used to ensure that the anchor bar is positioned at the center of the drilled borehole. It also facilitates complete grouting coverage around the entire anchor bar, enhancing stability and effectiveness.

| Sinodrills | Other Manufacturers | ||

| Dimensional Tolerances | Dimensional Tolerances | ||

| SDA Hollow Bar | Accessories | SDA Hollow Bar | Accessories |

| 0/-0.2mm | 0.25/-0mm | 0.5/-0.5mm | 0.4/-0mm |

Toughness is the ability of a material to absorb energy before breaking. Materials that don't change shape much when they break are called brittle. The Agt value is a key indicator of toughness. The Agt value is the percentage of total elongation at the point of fracture.

All Sinodrills SDA (Self-Drilling Anchor) bars are made with a minimum Agt value of 5% to ensure safety and reliability. This meets the strict quality and performance standards. This combination of strength and toughness makes the system durable and resilient, even under challenging conditions.

| Sinodrills SDA Hollow Bars | Other Manufacturers SDA Hollow Bars | ||

| Light Type | Standard Type | Light Type | Standard Type |

| Agt>6% | Agt>12% | Agt>5% | Agt>5% |

| 100% | 100% | <10% | <80% |

The certified system load is the final standard for all SDA (Self-Drilling Anchor) products. Sinodrills 100% guarantees that all SDA products meet this standard.

System tensile testing is a method of checking the strength of the entire assembly by putting it under stress. This includes the anchor bar, the coupler, the nut, and the plate. This testing process ensures that the whole assembly will perform reliably when there's a load on it, making sure it's safe and durable.

| Tensile Test | Snodrills | Other Manufacturers |

| Hollow Bar | 100% Pass | <80% pass |

| Hollow Bar Coupler | 100% Pass | <70% pass |

| Hollow Bar Coupler Anchor Nut Anchor Plate | 100% Pass | <60% pass |

In any structural system, consistency in quality is absolutely crucial. At Sinodrills, we are proud to deliver high quality. We do this by carefully selecting raw materials and using fully automated production lines. This ensures that every component of our self-drilling anchor system meets the highest standards of reliability and performance.

| Specifications | Sinodrills SDA Hollow Bars | Other Manufacturers SDA Hollow Bars | |

| Pass Rate | Ultimate Load | 100% | <80% |

| Yield Load | 100% | <80% | |

| Agt (5% or 12%) | 100% | <50% | |

| Loads Fluctuation | <15kN | >50kN | |