ERTi-5 (Titanium Grade 5) Titanium Welding Wire

Request a Quote

Welding Consumables

Titanium alloy filler metal for welding alloys of similar composition in applications requiring high strength and good weldability

- Chemical Designation: Ti-6Al-4V

- Standard: AWS A5.16

Chemical Composition (%)

| Fe | O | C | N | H | Al | V |

| ≤0.22 | 0.12-0.20 | ≤0.05 | ≤0.03 | ≤0.015 | 5.5-6.75 | 3.5-4.5 |

Features

- ERTi-5 offers excellent strength, making it ideal for applications requiring materials that can withstand high stress.

- This alloy performs exceptionally well in various corrosive environments, making it ideal for industries like chemical and others that demand corrosion-resistant materials.

- ERTi-5 maintains stable performance in high-temperature environments, ensuring reliable functionality under extreme conditions.

Applications

- Aerospace: Due to its lightweight, high strength, and corrosion resistance, ERTi-5 is widely used in aircraft engine blades, airframe structures, and landing gears, among other critical components.

- Shipbuilding and marine engineering: Known for its superior corrosion resistance, ERTi-5 is used in welding hull structures, propellers, and pipeline systems.

- Chemical equipment: ERTi-5 is commonly used in the manufacturing of reactors, storage tanks, and pipelines for industries requiring materials with chemical stability and corrosion resistance.

- Medical devices: Due to its non-toxic, corrosion-resistant, and easily weldable properties, ERTi-5 is widely used in the manufacturing of artificial joints, dental implants, and other medical implants.

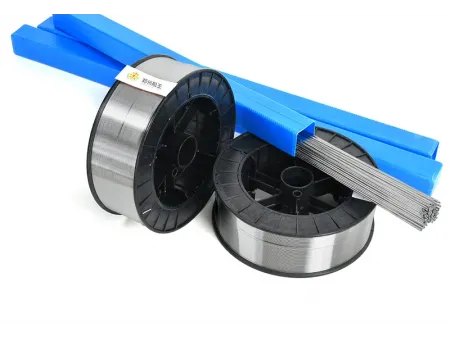

Packaging

- Welding wire diameter (fine wire spooling): 0.8mm, 1.0mm, 1.2mm, 1.6mm

- Package: D300mm (10kg/spool), D100mm (0.8kg/spool)

- Welding wire diameter (straight wire): 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (5kg/plastic box)

- Welding wire diameter (coil without spool): 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.0mm, 4.0mm, 5.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil