Wind Turbine Main Bearings

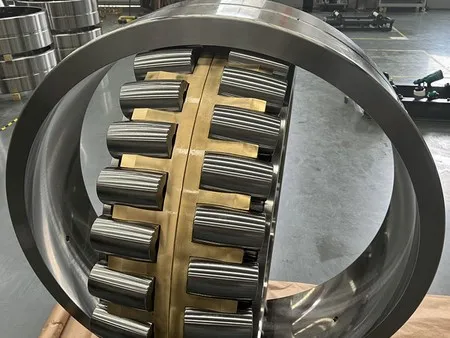

These double-row spherical roller bearings are specially designed for wind turbine main shafts. Their construction includes two rows of rollers, with the outer ring featuring a shared spherical raceway and the inner ring having two raceways angled relative to the bearing axis. This design enables the bearing to self-align, making it less sensitive to seat misalignment or shaft deflections, which are common in wind turbine operations. This self-aligning feature is particularly beneficial in situations where installation errors or shaft bending might occur, ensuring smooth and reliable operation.

Thanks to this self-aligning capability, the bearing can efficiently handle both radial loads and axial loads in either direction, making it highly versatile. It also has a high radial load capacity, which is crucial for managing the heavy loads and vibrations typical in wind turbine operations. The design also reduces the need for high precision in the housing, allowing for easier installation and reducing the risk of issues caused by minor errors or shaft deflections.

LYXQL manufactures these double-row spherical roller bearings for various wind turbine models, and they are widely used by leading companies such as Mingyang, Envision, and SANY. These bearings are chosen for their reliability and durability, ensuring that wind turbines operate smoothly and efficiently.

This combination of self-aligning properties and robust load-handling makes double-row spherical roller bearings a reliable choice for wind turbine main shafts, contributing to the overall efficiency and longevity of the turbines.

What are the common types of main shaft bearings used in wind turbines?

- Spherical Roller Bearings (SRB): Commonly used in double-fed systems and turbines below 5MW due to their strong misalignment tolerance.

- Tapered Roller Bearings (TRB) and Three-Row Cylindrical Roller Bearings (CRB): Typically adopted in direct-drive and semi-direct-drive turbines with larger capacities, offering greater axial and radial load support.

What limitations should be considered when using spherical roller bearings in wind turbines?

- Axial Load Ratio: To prevent early wear or failure, the axial load should not exceed 15–20% of the radial load.

- Lubrication: High-quality lubrication is critical for bearing longevity, particularly under heavy load and continuous rotation conditions typical of wind power generation.

What advantages does Xinqianglian offer in producing these specialized bearings?

- Trusted by Leading OEMs: We have long-standing partnerships with top Chinese wind turbine manufacturers, including Mingyang Smart Energy, Envision Energy, and Dongfang Electric.

- Advanced Manufacturing: Equipped with 61 state-of-the-art machines, including fully automated quenching machines from Italy’s SAIE, high-speed precision gear milling machines, and 5-axis CNC machining centers.

- Custom Engineering Solutions: We offer full customization, including adjustments to bearing dimensions, roller arrangements, sealing configurations, and lubrication systems to match the exact needs of specific turbine models.