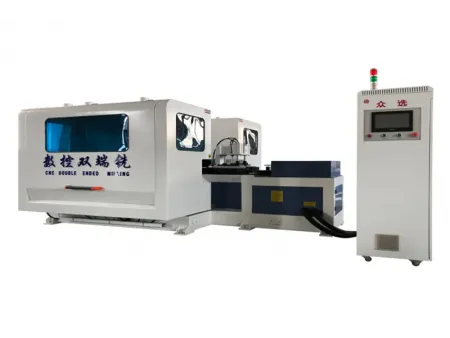

CNC Double-End Milling and Drilling Machine

Request a Quote

//Wood Door Machinery

Automatic CNC machine for wood door frame production

MXZ5170 CNC Double-End Milling and Drilling Machine (Single Rail Front Drill)

- Working length: 400-800mm

- Spindle diameter: Ø35mm

- Spindle speed: 9000r/min

- Milling motor power: 5.5kW×4pcs

- Drilling motor power: 1.5kW×2pcs

- Saw blade motor power: 1.5kW×2pcs

- Machine weight: 3500kg

- Machine dimensions: 3300×2100×1700mm

Applications

- Precision cutting of door rails to specified lengths.

- Double-end and rear-side drilling for accurate hole placement.

- Double-end shaping of door frame components.

Advantages

- Adjustable working width to accommodate various door rail sizes.

- Simple operation, all processes completed sequentially with a single “Start” command.

- High precision machining with effective edge protection to prevent chipping.

- High efficiency, capable of processing 100 to 120 door rails per hour.

MXZ5170B CNC Double-End Milling and Drilling Machine (Double Rail Front&Rear Drill)

- Working length: 340-920mm

- Spindle diameter: Ø40mm

- Spindle speed: 9000r/min

- Milling motor power: 5.5kW×4pcs

- Drilling motor power: 1.5kW×4pcs

- Saw blade motor power: 1.5kW×2pcs

- Machine weight: 3800kg

- Machine dimensions: 4400×2200×1700mm

Applications

- Precision length cutting of door rails.

- Drilling on both ends and both front and rear sides of door rails.

- Double-end shaping for consistent, accurate profiles.

Advantages

- Adjustable working width, with dual feeding rails to process wider timber sections.

- Simple operation, all functions executed with a single start command.

- High precision machining that prevents edge breakage.

- High productivity, capable of processing 90 to 100 door rails per hour.

Sample Showcase