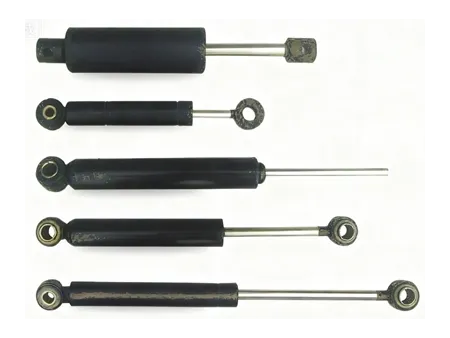

Damped Gas Springs (Gas Dampers)

Request a Quote

Gas struts with integrated damping for controlled motion and smooth operation in automotive, furniture and industrial applications

The working principle of damped gas springs is based on the compressibility of gas or an oil-gas mixture sealed within a closed cylinder. When a pressure difference forms inside the chamber, it drives the piston to move, providing both cushioning and stabilizing effects. These components play an important role in reducing vibration, minimizing the transfer of impact forces, and ensuring smooth and consistent system operation. One of the key elements, the oil seal, is produced in-house to guarantee product reliability and enable the development of special specifications according to customer requirements.

Structure

Materials and Surface Treatments

- Piston rod: Alloy steel / Stainless steel / Aluminum alloy

- Surface treatments: Chrome plating / Nitriding (QPQ)

- Cylinder and end fittings: Stainless steel / Alloy steel / Aluminum alloy

- Surface treatments: Alloy electroplating / Water-based paint / Oil-based paint

- Piston: Powder metallurgy / Aluminum alloy / Alloy steel

Technical Specifications

| d(mm) | D(mm) | S(mm) | L(mm) | Force F1(N) |

| 6 | 15 | 20-120 | 115-215 | |

| 8 | 18 | 50-200 | 180-480 | |

| 10 | 22 | 50-300 | 220-720 | |

| 12 | 27 | 100-300 | 320-720 | |

| 14 | 28 | 100-200 | 350-500 |

Compression and traction damping directions can be customized upon request.

Optional End Fittings

XW-1061Triangular ball stud bracket

XW-1062 Flat ball joint bracket

XW-1063 L-shaped ball stud bracket

XW-1064 Double-wing ball stud bracket

XW-1065 Plastic ball joint connector

XW-1066 Plastic ball socket

XW-1067 Metal ball socket

XW-1068 Eyelet end fitting

XW-1069 Gas spring mounting pin

XW-1070

Applications

Damped gas springs for automotive seats

Motorcycle shock absorbers

Washing machine vibration dampers