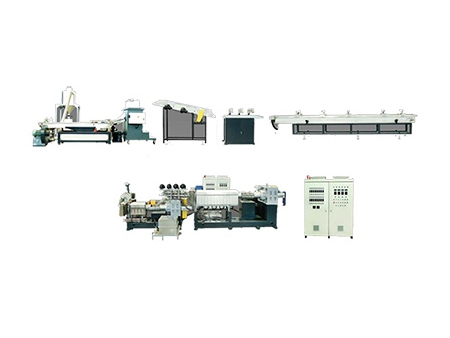

Rubber and Plastic Pelletizer/Granulator

Single-screw granulation machine for rubber and plastic

Single-screw granulator is mainly used for the filling, blending, modification, enhancement, chlorination of rubber, plastic and engineering resins. It is capable of processing of polypropylene and high water-absorbing resins, extrusion of degradable masterbatches, polycondensation of polyamide, polyurethane polymerization reactions, granulation of carbon powder and magnetic powder, as well as the production of insulation materials for cables, sheath materials, low-smoke halogen-free flame-retardant PVC cable materials, and various silane crosslinking materials. Our compact model (laboratory machine) is primarily used for scientific research and teaching.

-

PP/POE/EVA/PE 85% Caco3, talc filler masterbatch granulator

-

Carbon black masterbatch granulator

-

PVC pelletizing machine

Foaming masterbatch, XPE crosslinking masterbatch granulator

-

Rubber masterbatch, rubber accelerator, zinc oxide, sulfur masterbatch, rubber-plastics blending granulator

-

Rubber cable material (CPE,EPDM) granulator

- Low-smoke zero-halogen compounds and PVC cables

- Shielding and jacketing cable materials compounds for enhanced electrical performance

- Rubber cable compounds, including Chlorinated Polyethylene (CPE) and Ethylene Propylene Diene Monomer (EPDM)

- Advanced masterbatches such as rubber accelerators, sulfur, zinc oxide, foaming agents, XPE crosslinking, PP/PE calcium carbonate, talc, carbon black, and vibrant color masterbatches

- Engineering plastics and elastomers engineered for durability and flexibility

- Precision-formed rubber sheets including CPE/EPDM, fluoro rubber, and silicone rubber

- EVA plastic and automotive interior trim panels designed for aesthetic appeal and high performance