Metal surface laser cleaning machine

Model AHL-Q100

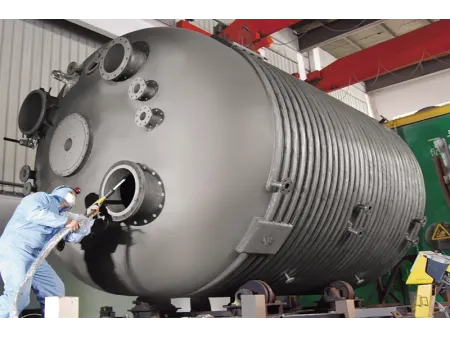

Application

Metal surface laser cleaning machines are used to clean mold surfaces and paint layers on metal surfaces and welding points, as well as remove oxides, oil pollution, grease stains and other product residues from a metal surface.

Principle

Laser cleaning technology, based on interactions between the laser and object surface, means using a high-energy laser to strip or evaporate pollution, rust or another coating. With no CFC, pollution, noise, or toxins, laser cleaning is an environmentally friendly cleaning method when compared to mechanical cleaning, chemical cleaning or ultrasonic cleaning methods. The thermal load and mechanical load of the substrate produced by the laser are small, making laser cleaning a highly effective, low cost, pollution free and safe cleaning method that causes no harm to operators or objects to be cleaned. What's more, the cleaning process an even be automatically controlled from long distances.

Feature

● The laser focuses energy onto a specific spot that has been predetermined by the operator, and will produce a laser that reaches extremely high temperatures in order to evaporate or dissolve dirt or other soiling materials.

● With a small divergence angle and easy directions, the concentration system allows the laser to have an extremely specific facula in a range of diameters without having to change the energy output.

● What's more, the energy density can also be adjusted to remove dirt though thermal expansion, which ensures there is no damage to the object's surface.