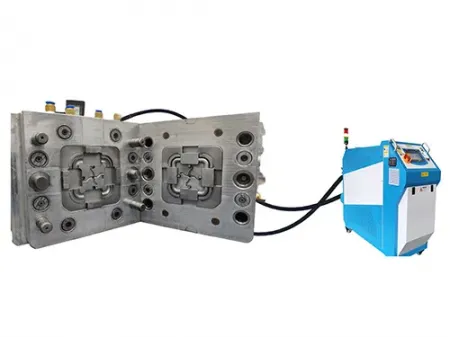

Mold Channel Cleaning Machine

Request a Quote

Mold waterway cleaning machine for automatic pulse cleaning of water circuit in molds

The mold channel cleaning machine is engineered for the automated cleaning of mold cooling channels, effectively removing scale, rust, and other deposits to improve cooling efficiency and extend mold service life. It offers both automated and manual cleaning modes, along with integrated flow detection, leak and pressure testing, and data recording and query functions, ensuring reliable performance and traceable maintenance.

Specifications

| Model | JNX-D2K |

| Power | 3.0kW |

| Water tank capacity | 100L |

| Number of water tank | 2 tanks |

| Input voltage | 380V/50Hz |

| Display | 7-inch display |

| Control system | PLC control system |

| Piping | Six in – Six out 3/8" (one group), One in – One out 1" (one group) |

| Pipe diameter | DN25 |

| Intake air pressure | min. 0.4MPa |

| Ambient temperature | 5~65℃ |

| Booster pump | 0.6-0.9MPa |

| Cleaning water pressure | 0.2-0.5MPa |

| Cleaning air pressure | 0.6-0.9MPa |

| Machine dimensions | 160×50×120cm |

| Machine weight | 320kg |

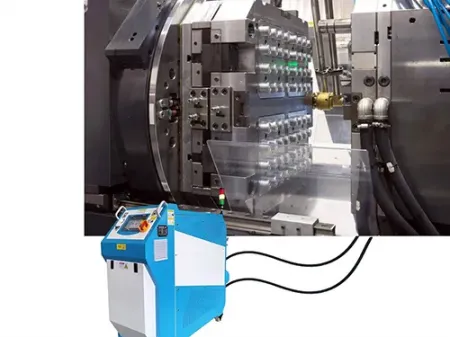

Applications

- Injection molding

- Die-casting molds

- Rubber mold production

- Food processing mold cleaning

- Medical device mold maintenance

Key Advantages

- Chemical-Free Cleaning Utilizes cavitation technology for purely physical descaling, eliminating need for harmful chemicals and ensuring eco-friendly operation.

- Smart Control Integrated intelligent system supports multiple modes (cavitation, pulse, unidirectional/bidirectional flow) with adaptive settings for different mold channels. Includes self-diagnostic functions.

- Dual-Tank Design Separate tanks for cleaning and rinsing prevent cross-contamination and ensure residue-free results.

- Auto Drying Automatically blows residual water from pipelines into tanks during/after cleaning, preventing leaks during disassembly and rust from moisture retention.

- Energy Efficiency Adopts variable frequency energy-saving design, automatically stabilizing pressure based on pipeline size to provide consistent water pressure and reduce energy consumption.