Digital Ceramic Printing Machine

Digital Ceramic Printing on Ceramic

The digital ceramic printing machine for ceramics is an advanced industrial device that integrates digital inkjet printing technology with high-temperature sintering. It is specifically designed for printing high-precision, high-performance ceramic coatings or 3D structures directly onto ceramic substrates or other compatible materials. The core technology involves using high-precision printheads to deposit nano- or micron-scale ceramic slurry/ink layer by layer. The printed substrate is then subjected to high-temperature sintering (1200-1600℃), densifying the ceramic particles and forming parts or decorative layers with specific mechanical, electrical, or thermal properties. This innovation overcomes the limitations of traditional ceramic molding processes, supporting complex geometric structures, functionally graded materials, and small-batch customization. It is widely used in the electronics industry, aerospace, medical devices, and artistic design.

- Max. resolution 1600 dpi

- Max. printing area 3300×7000mm

- Firing temperature 1200-1600℃

| Model | DXPG2538/DXPG2550/DXPG3060/DXPG3370 |

| Printhead brand | StarFire, Xaar |

| Printhead quantity | 6/12/18 |

| Max. resolution | 1600 dpi |

| Max. printing speed | 20/40/60 m²/h |

| Max. printing area | 2500×3800/2500×5000/3000×6000/3300×7000mm |

| Material thickness | 0-50mm |

| Ink type | eco-friendly ceramic inks |

| Ink color | C, M, Y, K, G, W |

| Input format | PDF, JPEG, TIFF, EPS, AI |

| Power consumption | 20-35 kW |

| Electrical requirement | Configurable according to local voltage and frequency requirements. |

| Environmental requirement | Independent, clean, dust-free, low light exposure, and well-ventilated. |

| Ambient temperature | 22℃ to 28℃(72℉ to 82℉) |

| Relative humidity | 40%-70% (non-condensing) |

- High-Precision Digital Inkjet System

- Ultra-Fine Printhead Technology: Equipped with industrial-grade printheads capable of depositing ceramic slurry with nanometer or micrometer precision, achieving resolutions up to 1600 dpi.

- Multi-Layer Printing: Allows for layer-by-layer printing of ceramic material, supporting the creation of 3D structures, gradient patterns, and detailed surface textures.

- Advanced Sintering Process

- High-Temperature Sintering: Operates at 1200-1600℃ to densify ceramic particles, enhancing structural integrity and durability.

- Intelligent Temperature Control: Automatically adjusts heating rates, peak temperatures, and cooling cycles to prevent cracking and ensure stable bonding.

- Functional Gradient Capabilities: Supports multi-material printing for gradient properties, enabling components with varied electrical, thermal, or mechanical characteristics.

- Broad Material Compatibility

- Supports various ceramic substrates, including alumina, zirconia, and silicon carbide.

- Compatible with non-ceramic materials when coated with appropriate ceramic inks.

- Electronics Industry: Ceramic PCBs, insulating layers, capacitors

- Aerospace: Heat shields, ceramic bearings, turbine components

- Medical Devices: Dental ceramics, biocompatible implants, prosthetic components

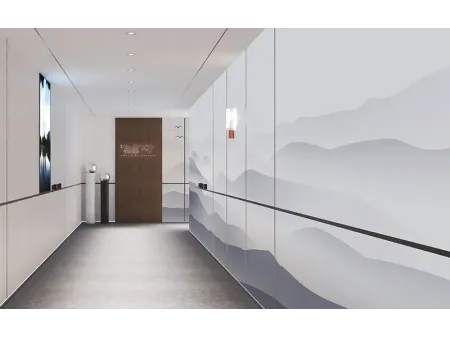

- Artistic Design: Ceramic tiles, decorative plates, sculptural art