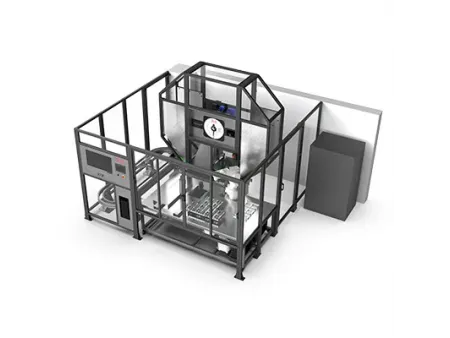

Robotic Automated Charpy Impact Testing System

The robotic Charpy impact testing platform integrates a pendulum impact tester with an ABB industrial robot, vision-based notch alignment, a low-temperature conditioning chamber, intelligent electrical control, and dedicated automation software.

This fully automated solution completes the entire process from specimen identification to impact testing and data upload, without manual intervention, significantly enhancing throughput, accuracy, and laboratory safety.

Operators simply place specimens of various shapes and sizes into the storage rack. Until results are transmitted to the host database, every step is executed automatically: robotic pickup, dimensional measurement, barcode identification, sorting, low-temperature conditioning, vision-guided notch alignment, specimen placement onto the anvil, impact execution, post-test removal. All specimen types with various thicknesses can be tested under low-temperature conditions without making any manual adjustments. The testing platform is designed for high throughput, operator safety, and test repeatability, with integrated automatic fault detection and alarm functions to ensure reliable long-term operation.

ISO 148, EN10045, ASTM E23, GB/T 229, GB11291.1, GOST 9454, ISO13850

Charpy impact test

- Each tray accommodates 30 specimens; up to 90 specimens can be conditioned simultaneously.

- High-precision temperature control within ±0.5°C.

- Robotic transfer from the alcohol bath to the impact position takes less than 5 seconds, fully meeting Charpy low-temperature testing requirements.

- Vision-guided centering achieves notch alignment accuracy within ±0.1mm.

- Dimensional measurement and barcode scanning reach a resolution of ≤0.02mm.

- Supports high-resolution acquisition for impact analysis (optional).

- Robot access is prevented unless the chamber door is fully open.

- Robot will not place an empty tray onto an occupied station under specimen tray position detection.

- System stops immediately if either side access panel is opened.

- A force-sensing trigger halts the robot when unexpected resistance is detected. After manual repositioning to a safe location, it resumes its programmed path.