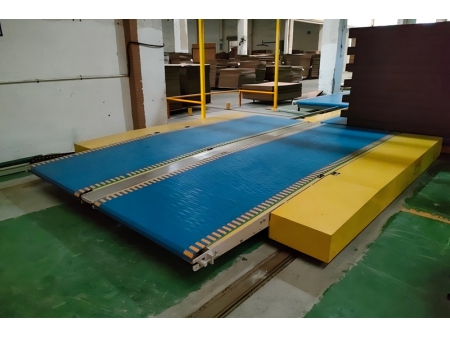

Automatic Corrugated Board Unloading Cart

Request a Quote

The automatic corrugated board unloading cart system consists of an unloading cart and pneumatic board-stopping gates, designed for automatic transfer of corrugated board stacks onto pallets. Through precise positioning and unloading control, cut boards are neatly stacked onto wooden, plastic, or metal pallets in accordance with preset specifications. The unloading cart system replaces traditional manual palletizing, enabling seamless connection from the production line to warehouse logistics and significantly reducing labor costs and board damage. It has become a core solution for high-capacity carton plants to improve loading efficiency and reduce labor intensity.

- Full-Scenario Loading Adaptability: Supports board widths of 1.8–2.8 m and cutting lengths of 2.5–2.8 m, making it compatible with multiple pallet materials. In addition, it features one-click parameter switching for flexible production.

- High-Precision Stacking Control: Features an automatic positioning combined with pneumatic board gates and adjustable mechanisms, ensuring smooth unloading onto pallets.

- Dual-Mode Efficient Operation: Flexible manual/automatic modes that are freely switchable. The board unloading cart offers a maximum load of 2000 kg, with an unloading speed of up to 30 pallets/hour.

- Core equipment: Unloading cart pneumatic board-stopping gates

- Drive power: 2.2 kW (travel motor)

- Maximum load: 2000 kg

- Board sizes: Width 1.8 / 2.2 / 2.5 / 2.8 m; cutting length ≤2.8 m

- Board gate structure: 140 × 140 mm square tube frame 18 mm plywood

- Control mode: PLC control