DPH190/220/250/260 Dual-Servo Alu-PVC Blister Packaging Machine

Pharmaceutical Packaging Machinery Since 1998

Alu-PVC blister packaging machine is suitable for tablet packaging and supports PVC, PTP, PDVC, PET, and Aclar films. The equipment features pressure forming, heat sealing, batch coding, and punching for automated pharmaceutical production.

| Model | ||||

|---|---|---|---|---|

| Cutting efficiency | 20-120 cuts/min | 20-120 cuts/min | 20-120 cuts/min | 20-180 cuts/min |

| Max. forming area | 190 × 200 mm | 220 × 200 mm | 250 × 200 mm | 260 × 200 mm |

| PVC film | 190 × 0.15 to 0.45 mm | 220 × 0.15 to 0.45 mm | 250 × 0.15 to 0.45 mm | 260 × 0.15 to 0.45 mm |

| PTP aluminum foil | 190 × 0.02 to 0.03 mm | 220 × 0.02 to 0.03 mm | 250 × 0.02 to 0.03 mm | 260 × 0.02 to 0.03 mm |

| Power supply | 380 V, 50 Hz | 380 V, 50 Hz | 380 V, 50 Hz | 380 V, 50 Hz |

| Total power | 12 kW | 12 kW | 12 kW | 12 kW |

| Dimensions | 2900 × 880 × 1500 mm | 3300 × 950 × 1700 mm | 3510 × 1050 × 1700 mm | 3510 × 1050 × 1700 mm |

| Weight | 1500 kg | 2200 kg | 2500 kg | 2500 kg |

| Forming method | Pressure molding | Pressure molding | Pressure molding | Pressure molding |

| Sealing method | Roller sealing | Roller sealing | Roller sealing | Roller sealing |

| Noise level | 75 dB(A) | 75 dB(A) | 75 dB(A) | 75 dB(A) |

| Max. forming depth | 18 mm | 18 mm | 18 mm | 18 mm |

| Compressed air consumption | 1.1 m³/h | 1.1 m³/h | 1.1 m³/h | 1.1 m³/h |

| Compressed air pressure | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa |

| Cooling water consumption | 0.19 m³/h | 0.19 m³/h | 0.19 m³/h | 0.19 m³/h |

| Model | | | | |

|---|---|---|---|---|

| Output capacity | 1.296 million units per shift (3 blisters per stroke, 10 units per blister, 90 cuts/min, 8 hours per shift) | 1.296 million units per shift (3 blisters per stroke, 10 units per blister, 90 cuts/min, 8 hours per shift) | 1.728 million units per shift (4 blisters per stroke, 10 units per blister, 90 strokes per cuts, 8 hours per shift) | 1.92 million units per shift (4 blisters per stroke, 10 units per blister, 100 cuts/min, 8 hours per shift) |

| Typical application | Entry level model suitable for R&D and small batch production with limited output requirements and budget | Standard model for small to medium batch production, meeting mainstream production needs | General purpose model with medium output capacity and strong versatility | High demand model for medium to large batch production with higher output requirements |

-

- Forming station

-

- Indexing and traction station

-

- Feeding station

-

- Heat sealing station

-

- Batch coding and perforation station

-

- Punching station

Products with high moisture and light protection requirements are better suited for aluminum cold forming blisters. Conventional products can be packaged using aluminum plastic thermoformed blisters, which offer a more cost-effective solution.

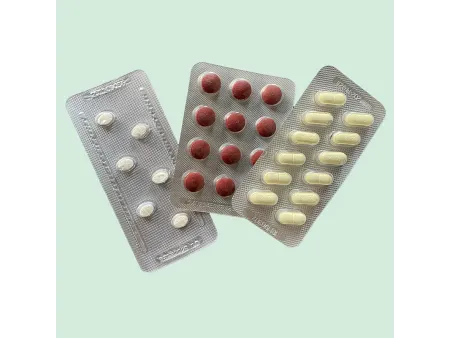

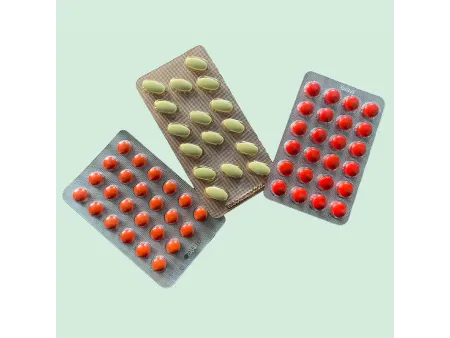

Aluminum plastic blister packaging machines are suitable for packaging solid dosage forms of various shapes, including tablets, capsules, and irregular shaped products. Applicable packaging materials include PVC, PVDC, PET, and Aclar.

The typical process includes material unwinding, forming, filling, heat sealing, and punching. All stages are controlled automatically, ensuring stable operation and simplified handling.