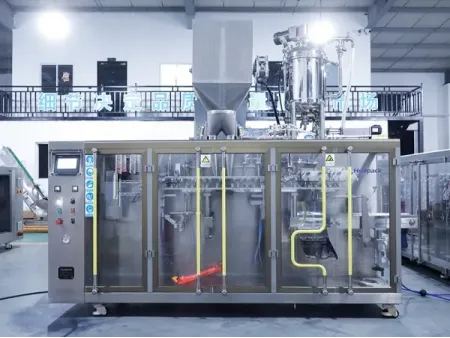

Premade Pouch Packaging Machine, 2-Nozzle Filling

Request a Quote

210DG

These premade pouch packaging machines are intended for small-volume products, typically up to 250 ml. They use a two-nozzle filling setup, so two pouches are handled at the same time, which helps increase output without making the line more complex. The process covers pouch pick-up, opening, filling, and sealing in a synchronized way, and is commonly used for cosmetics, food, pharmaceuticals, health supplements, and pet food, especially for small and premium packs that need stable filling and neat sealing.

Applications

Process Flow

- Dual pouch loading

- Dual pouch pick-up

- Dual pouch opening

- Dual air blowing (pouch opening air assist)

- Dual filling

- Dual pouch expanding

- Heat sealing

- Cooling sealing

- Finished pouch discharge

- Finished pouch conveying

Features

- These premade pouch packaging machines can package various pouch styles in a stable way, including three-side seal, four-side seal, stand-up pouches, and special-shaped pouches.

- Different filling systems can be selected depending on the product, so the same platform can be used for powders, granules, liquids, and viscous materials without changing the basic structure of the packaging machine.

- All main parts in contact with the product are made of 304 stainless steel, together with anodized aluminum components and food-grade plastics, meeting GMP requirements for food and pharmaceutical applications.

- The pouch packaging machine is equipped with PLC control to coordinate the motions of pouch pick-up, opening, filling, and sealing, so each step runs in sync and the whole process stays smooth and stable during continuous production.

- A pouch opening detection function is included, so filling only takes place when the pouch is correctly opened, reducing product waste. Sealing is also blocked when no product is filled, which helps avoid unnecessary use of packaging material.

- The two-nozzle configuration allows two pouches to be processed in each cycle, bringing an efficiency increase of more than 80% compared with single-nozzle equipment. The combined theoretical output can reach up to 100 pouches per minute.

- According to production needs, the pouch packaging machine can be equipped with additional systems such as coding machines, checkweighers, cartoners, case packers, labeling machines, and palletizers, so the line can be expanded into a more automated setup, with less manual handling.

Specifications

| Model | 210DG | |

| Packaging parameters | Min. pouch size (W × H) | 70×130mm |

| Max. pouch size (W × H) | 105×300mm | |

| Max. filling volume | 250ml | |

| Packing speed (pouches/min) | ≤100 | |

| Equipment specifications | Machine dimensions (L × W × H) | 2550mm×1100mm×1400mm |

| Total machine weight | 1100kg | |

| Operating conditions | Ambient temperature | -10℃-+55℃ |

| Relative humidity (non-condensing) | <85% | |

| Power supply | AC380V, 50Hz | |

| Working air pressure | 0.6Mpa | |

| Air consumption | 560L/min | |

| Main motor power | 3.5Kw | |

Optional Functions

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

Details

Gripper system, product hopper, conveyor system, filling unit

Customer Case Studies

How can a medium-scale food manufacturer improve productivity when moving to premade pouch packaging?

How can a medium-scale food manufacturer improve productivity when moving to premade pouch packaging?

Configurations with two filling nozzles or multiple working stations allow higher output while keeping daily operation simple. Processes such as pouch loading, opening, filling, and sealing are carried out in a smooth and well-coordinated sequence, so medium-size food factories can upgrade their production lines, increase output, and keep daily operation stable and easy to control.

What helps maintain hygienic filling conditions in food and beverage applications?

What helps maintain hygienic filling conditions in food and beverage applications?

To keep the filling process clean and hygienic mainly depends on using food-grade materials on all product-contact parts and an enclosed filling structure. Using stainless steel on the parts that come into contact with the product, together with smooth internal surfaces and a closed filling design, helps keep the product separated from the outside environment.