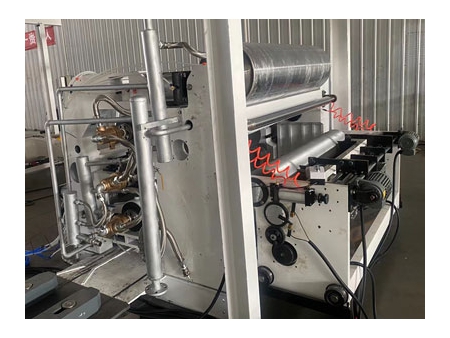

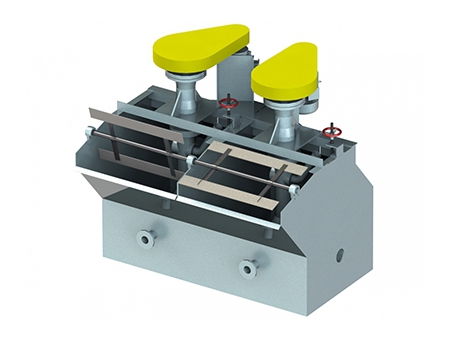

Single Facer with Cassette, SF-MW10

Request a Quote

Corrugated Board Manufacturing

| Design speed | 100m/min |

| Working speed | 80m/min |

| Temperature range | 160-200°C |

| Steam pressure | 0.8-1.3Mpa |

| Air pressure | 0.4-0.9MPa |

| Flute type | (UV or UVV) |

| Corrugator Roll Dia. | Ø280mm |

Features

- Tungsten carbide or alloy steel can be used as the material of corrugator roll;

- Cassette type single facer provides quick flute change;

- Paper feeding is carried out by using vacuum absorption method, a high-pressure blower is equipped to ensure the stable corrugation process at high speed;

- The width of groove on lower corrugating roll is less than 2mm, efficiently preventing the marks of stripes on corrugated cardboard;

- Universal joint transmission system is adopted to reduce vibration, enabling the operation more stable and reliable;

- Reduction gearbox is designed with oil-immersed lubrication to lower the machine vibration;

- Automatic glue feeding, pneumatic control of glue application and return can provide cushion effect;

- Engraved glue applicator roll is chrome plated;

- Upper and lower corrugating rolls are made of 48CrMo high grade alloy steel;

Other Products You May Like

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos