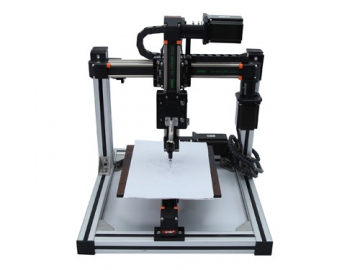

4-Axis Vision Guided Dispensing Robot

The 4-axis vision guided dispensing robot is a high-speed, high-precision and fully automatic on-line jet dispensing system based on semiconductor packaging and SMT’s latest technology requirements. The robot utilizes a more stable marble frame structure, more efficient motor drive, piezoelectric jetting valve and a dustproof design. It meets the increasingly strict requirements of jetting dispensing process and the stability of the system in the industry. It is mainly used in wafer/chip primary packaging of under fill, overfill, and edge bond, SMT second-level packaging of under fill, encap, overfill and other processes.

- FPC/PCB

- Wafer/chip primary packaging of under fill, overfill, and edge bond and other processes

- SMT second-level packaging of under fill, encap, overfill and other processes

- MEMS microphone

- MEMS barometer

- CCM

- Fingerprint identification

Features

The system integrates rich process components

You can choose the bottom heating, automatic weighing, automatic cleaning, laser altimetry, on-line UV exposure, plasma air gun and other functional modules combination.

Pertinence

According to the characteristics of semiconductor packaging and the SMT industry, it can be equipped with machines for preheating and material testing of the previous process, as well as for insulation and operation quality testing of the next material. It also further improves the intelligence level, improves the production yield and stability of the system.

| Model | GS-600 |

| Structure | Floor type, in-line (marble frame + mobile gantry) |

| Axis No. | 3axis |

| Dispensing area (W*D) | 350×470mm |

| Motion range X/Y/Z (mm) | 400/600/30 |

| Max speed X/Y/Z (mm/s) | 1000/1000/500 |

| RP accuracy | ±0.01mm |

| Max acceleration speed X/Y/Z (g) | 1.2/1.2/0.5 |

| Transmission type | Linear motor + grating |

| Z axis load(kg) | 5 |

| Conveyer belt load (kg) | 3 |

| Max substrate width (mm) | 10 |

| Conveyer rail height range (mm) | 890~965 |

| Conveyer rail | Anti-static and high temperature 6mm flat belt, the standard edge clearance 3mm |

| Rail width's range | 55mm~515mm |

| Conveyer speed | 300mm/s |

| Programming type | Developed from PC |

| Camera pixel (M) | 130 |

| Weight (kg) | 800 |

| Dimension (L*W*H) (mm) | 770×1250×1900 |

| input voltage | 220V AC 50Hz |

| work environment | Temperature 0-40℃, humidity 20-90% (no condensation) |

| |

- GS-600 cabinet three-axis motion platform

- Visual identification system

- Cleaning/calibration module

- Laser height measuring module

- Sound-light alarm module

- Pneumatic stabilization module

- Low liquid level detection

- Monorail transmission module

- Piezoelectric jetting module

- Pneumatic jetting module

- Weighing module

- Track heating module

- Tooling adsorption module

- Double track

- Automatic loading/unloading module

industrial robot, glue dispenser, liquid dispersing