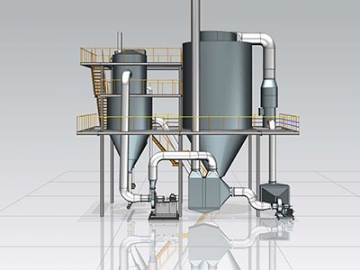

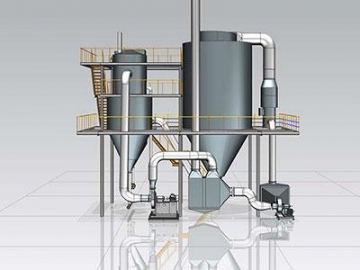

YPG Pressure Nozzle Spray Dryer

Overview

The YPG pressure nozzle spray dryer is provided with drying and pelletizing functions. It produces liquid feedstock into spherical particles as desired by adjusting feed pump pressure, flow rate and orifice size.

Working Process

The liquid feedstock is inhaled into diaphragm pump under the action of high pressure, and then is ejected in form of vaporous droplets. These droplets decline along with hot air in parallel flow and most of particles is aggregated at discharge gate of tower bottom.

Segregated by cyclone separator, exhaust gas is expelled via suction fan of this pressure nozzle spray dryer, and tiny powder is collected by specialized powder-collecting container configured under the cyclone separator. Secondary dedusting device can be equipped at suction fan outlet, thus recovery rate of this spray drying equipment reaches more than 99%.

Features

1. Our pressure nozzle spray dryer is highlighted by fast drying speed. The surface area of atomized liquid feedstock is largely increased, thus 95%-98% moisture can instantly evaporate within a very short time under the action of hot airflow. Hence, this machine is well suited for heat sensitive material drying.

2. Final products come with uniform particle size, excellent liquidity and solubility.

3. Atomization is conducted under small driving force.

4. This pressure nozzle spray drying machine has extremely wide application range. Except hot air drying, it also fits for cold air pelletizing, characterized by strong material adaptability.

5. With easy access to automated operation, this pressure nozzle spray dryer is user-friendly and easy for control.

Application Scope

This pressure nozzle spray dryer is well suited to following industries:

1. Chemical engineering: Organic catalyst, resin, synthetic detergent, grease product, thiamine, dye, dye intermediate, silica hydrated, plumbago, ammonium dihydrogen phosphate, etc.

2. Food: Amino acid, flavoring, protein, starch, dairy product, coffee extract, fish meal, meat flavor, etc.

3. Pharmaceutical: Chinese patent medicine, pesticide, antibiotic, dissolved medicine, etc.

4. Porcelain: Magnesium oxide, china clay, metallic oxide, dolomite, etc.

5. Spray granulation: Fertilizer, alumina, ceramic powder, pharmacy, heavy metal, extra hard steel, granular detergent, Chinese patent medicine, etc.

| Model / Item | |||||||||

| Evaporation capacity (kg/h) | 50 | 100 | 150 | 200 | 300 | 500 | Parameters depend on actual situation. | ||

| Diaphragm pump | Power (KW) | 4 | 7.5 | 11 | 15 | 22 | 30 | ||

| Pressure (MPa) | 0.6-5 (according to material experiment effect) 1-3 (for general operation) | ||||||||

| Heating method | Electrical | Electrical steam | Electrical air heating furnace by using coal or oil | ||||||

| Tower diameter (mm) | 1800 | 2400 | 2600 | 2800 | 3200 | 3800 | |||

| Total height (mm) | 9200 | 11600 | 14000 | 15300 | 17100 | 19000 | |||

Remarks:

1. Generally, evaporation capacity is related to material characteristic. Yet, the evaporation capacity in this table is related to temperature.

2. Atomization pressure and pump model are determined by particle size and actual material handling capacity.