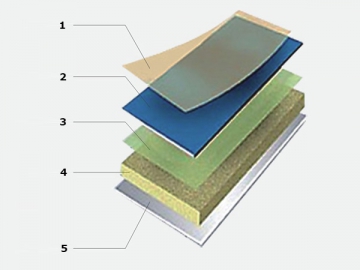

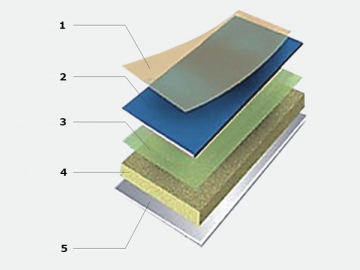

EPS Sandwich Panel

1. Protective film

2. Color steel palte

3. High strength adhesive layer

4. Non-combustible sandwich layer materials(EPS)

5. Color steel plate

Introduction

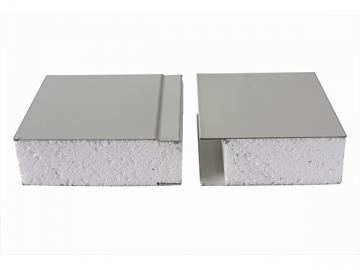

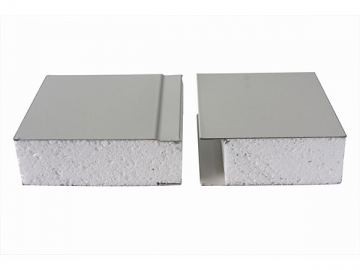

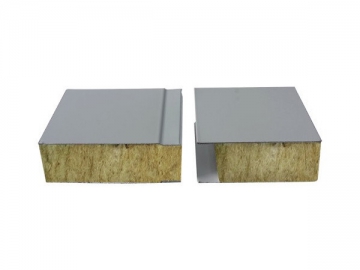

The EPS sandwich panel is a foam core panel that serves as a structural insulated panel. It adopts the color steel plates as surface layer, the flame-proof polystyrene foam board as sandwich material, and the two-component urethane as the adhesive. The EPS composite panel is formed by continuous heating and compression, and then sheared by scaled synchronous cutting. The adhesive combines the foam board and two layers of steel plates. The panel can bear heavy loads, with a compressive strength of 100kPa.

Specification

Steel thickness: 0.3mm-0.7mm

Sandwich thickness: 50mm-250mm

Width: 950mm, 1150mm

Length: can be customized

Features

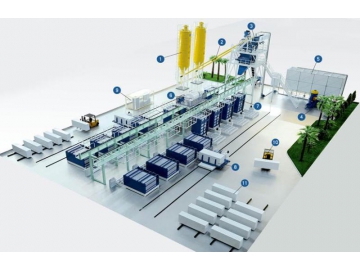

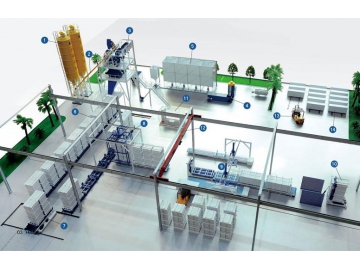

1. We have automatic equipment to achieve the continuous production of EPS sandwich panel. All the main processes are controlled by computer. The quality is in line with the industrial standard in China. The fire-proofing grade is B3.

2. The weight per square meter is only 10-12 kg. The panel shows excellent heat insulation performance, with a thermal conductivity of λ=0.032 KW/m.h.℃.

3. With every detail enhanced, our superb workmanship endows our panel with the best performance. There are waves on the surface of the roof panel, so the panel is stronger than similar products.

4. The fixing is tight and reasonable. We use M6 self-trapping screw to fix the roof panel to the purlin. To avoid leakage, we set the screw on the wave position of the roof panel, and the screw also goes through special treatment.

5. The EPS sandwich panel will buckle each other, which avoids the leakage from the roof panel and save fittings.

6. We cover the panel with polythene films to protect the steel surface from scratches during installation and transport.

| Item | Unit | Index of Properties | ||

| Ⅰ | Ⅱ | Ⅲ | ||

| Apparent density ≤ | kg/m2 | 15.0 | 20.0 | 30.0 |

| Compression strength (Compressive stress under 10% deformation) ≥ | kPa | 60 | 100 | 150 |

| Thermal conductivity coefficient ≤ | w/(m.k) | 0.041 | 0.041 | 0.041 |

| Water vapor permeability coefficient ≤ | ng/Pa.m.s | 9.5 | 4.5 | 4.5 |

| Water absorbing capacity ≤ | % | 6 | 4 | 2 |

| Oxygen Index ≥ | % | 30 | 30 | 30 |

Note:

Class Ⅰ: does not load.

Class Ⅱ: bears load.

Class Ⅲ: bears heavy load.