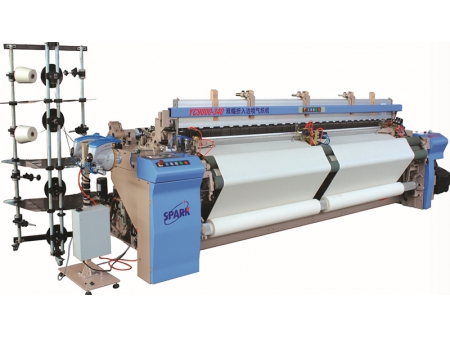

Energy-saving Device for Air Jet Loom

Are you worrying about how to detect the gas leakage location and reduce the energy consumption? If so, our energy-saving device for air jet loom may save you from the troubles.

The power consumption of the air compressor takes up 80% to 85% that of the total energy consumed by the equipment. Compared with the air consumption in normal operating state, leakage at all parts of the machine can cause 20% to 80% increase in air consumption, or even more. Our gas consumption monitoring device can supervise the equipment operation at any time, which effectively reduces the air consumption, improves weaving efficiency, and saves the operating cost.

Widely used by the weaving machine manufacturer and the end customers, our energy saving device for air jet loom has the following features.

1. Installed at the inlet of the air jet loom, this product can be used for real-time monitoring of instantaneous gas consumption and the overall gas consumption.

2. Generally, the instantaneous gas consumption of each air jet loom is basically constant. Leakage or other fault related to source gas can be reflected by the value instantly. Our leak detection equipment for air-jet loom can identify the leakage positions immediately, such as loom, pipeline, solenoid valve, parts, and some others.

3. By reason of the big noise and the fast speed of the air jet loom, it is difficult for the operator to realize the occurrence of gas leakage. Additionally, under full load operating state, the air compressor will cause great increase in power consumption, which leads to energy waste, consequently. Our energy-saving device for air jet loom will send out a sound and light alarm, reminding the operators to take the appropriate measures.

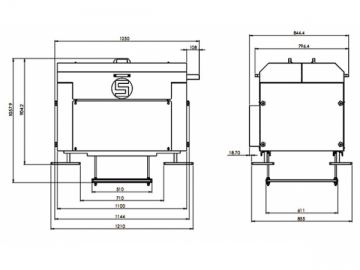

Installation Instruction of Energy-Saving Equipment For Textile Factory| Pressure gage | ||||

| Energy saving device | Air-jet loom | |||

| Intake tube | Air outlet pipe | |||