Vision-guided Dispensing Robot (with High Precision Dispensing Valve)

Introduction

VS-C series vision-guided dispensing robot is one intelligent visual identity robot system, designed & developed for smart phone electronics, smart wearable electronics, LED, optical communication, etc. The system can be qualified for dispensing of electronics core filling, pin coating, FPC reinforcing, CCM & VCM assembling, smart-phone frame & LCD edge gluing, fingerprint recognition core & module assembling, NFC model assembling, flat motor assembling, linear vibration motor assembling, smart-phone speaker & receiver assembling.

Product Features:

The vision-guided dispensing robot with high precision dispensing valve features vision recognition software system is developed for the characteristics of CCM and VCM technology.

As for focus running and wire drawing when needles lens during manual dispensing, the piezoelectric injection valve can be chosen for non-contact dispensing operation.

As for the possible level deviation in lens focusing, and the height fluctuation caused by tooling, altimetry function can be used to eliminate the error.

Solution Advantages:

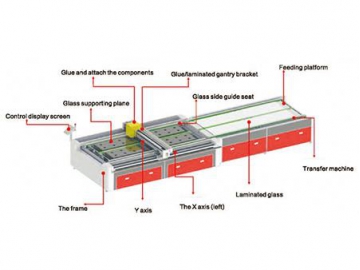

Vision dispensing robot is new model based on the 3D motion platform of the servo wire rod. It can realize high precision positioning, fast coating efficiency, and high qualification rates of finished products.

Mingseal’s self-design visual software and operating system makes the fixture easy to install and debug, and the visual system easy to operate and understand.

Solution:

VS-300C/200C vision dispensing robot configurations: SS-300C platform ZS-200.001 vision system ZS-GY-100 dispensing process module PZT-JET5010 piezoelectric injection valve

| Model | | |

| structure | gantry type | gantry type |

| Axis NO. | 3 | 3 |

| Move distance (axis X/Y/Z) | 300/300/100 mm | 200/200/100 mm |

| Repeat positioning accuracy (axis X/Y/Z) | ±0.005mm | ±0.005mm |

| Resolution Ratio (axis X/Y/Z) | 0.002mm | 0.002mm |

| Loading plate load | 10KG | 10KG |

| Axis Z load | 5KG | 5KG |

| Power | 450W | 450W |

| Driving type | AC servo motor | AC servo motor |

| Transmission type | Lead screw | Lead screw |

| Lead distance | X/Y-20mm, Z-10mm | X/Y-20mm, Z-10mm |

| Oversize(L W H/mm) | 576×514×626 | 476×414×626 |

| Program type | based on PC | based on PC |

| Camera pixel | 1,300,000 pixels (higher pixels as optional) | 1,300,000 pixels (higher pixels as optional) |

| Light source | LED coaxial light(blue or red) | LED coaxial light(blue or red) |

| I/O | 12in / 12out | 12in / 12out |

| Wet. | 65kg | 57kg |

| Tasks memory | 120pcs | 120pcs |

| Input Voltage | 220V AC 50Hz | 220V AC 50Hz |

| Working environment | Temperature 0-40 ℃ Humidity 20-90% | Temperature 0-40 ℃ Humidity 20-90% |

| Remarks: VS-200C cannot matched with laser altimeter module | ||

Attachments

Standard:

10cc, 30cc, 50cc glue feeding device

Dispensing point assistant positioning device

Automatic vacuum glue cleaning function

Optional:

Nozzle height automatic correcting device

Pixel & target calibration

Dispensing point/width detection

Vision calibration module

Laser altimeter model

Low liquid detection

Fixture vacuum adsorbing device

Piezoelectric type dispensing valve / Piezoelectric type dispensing valve( hot-melt adhesive ) / pneumatic type jet dispensing valve / high precision rotary auger valve

venting valve