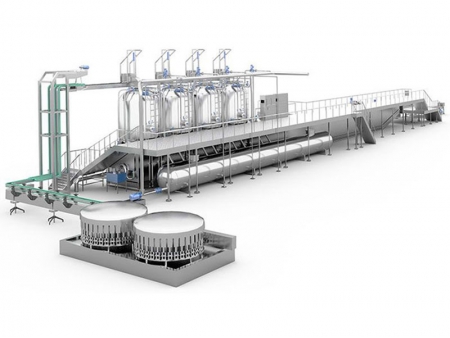

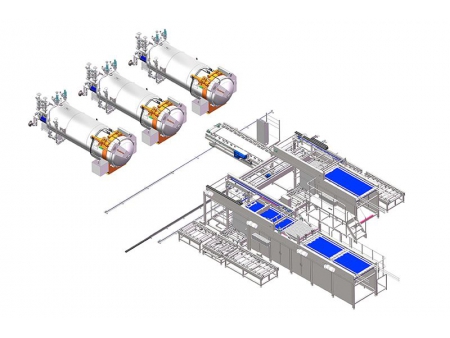

Continuous Sterilization Equipment( Vertical Retort for Sterilizing Metal Cans)

Mainly applicable for products packaged with three-piece tin can, the continuous sterilization equipment boast high sterilization efficiency, effectively minimizing steam usage and environment pollution. Also, the vertical retort incorporates advanced integrated loading system without the need for manual loading, significantly lowering labor intensity, energy consumption and occupied space under the same output.

DTS is a leading autoclave sterilizer supplier in the Chinese sterilization equipment industry. We always endeavor to provide our clients with extremely satisfactory retorts. We assure you these continuous retorts are exceptional and well worth buying.

Features

1.Efficient, Energy-Saving, Environment-Friendly, Full-Automatic, Continuous, Crateless, High-Temperature Sterilization Line

The vertical retorts are delicately developed by absorbing advanced domestic and overseas food and beverage sterilization technologies and catering to the demand of domestic and overseas food and beverage industries.

2. High Technology Threshold, Stable Performance and High Practicability

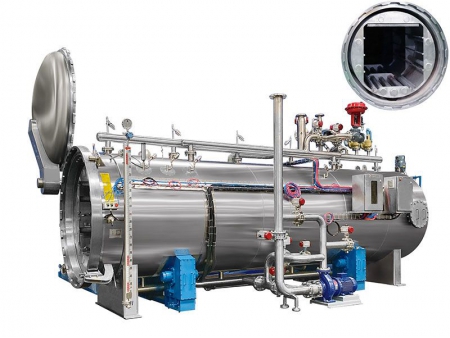

The sterile equipment are made of top-quality materials using cutting-edge technologies, ensuring they can operate stably in a longer service life.

3. Leading-Edge Sterilization Process and Satisfactory Sterilization Result

Taking high-temperature steam as sterilization medium, resorting to top entry and balanced injection, the continuous sterilization equipment achieve extremely balanced heat distribution during sterilization.

4. Dynamic Image Display

Process flow can be easily understood because running status will be displayed by indicator lights and corresponding images on touch screen.

5. Adjustable Parameters like Pressure, Temperature and So On

The vertical retorts have a wide application and high adaptability. Thanks to the relatively big adjustable range of temperature and pressure of control components, the retort sterilizers allow for both automatic control and manual control during the whole process. The manual control means you are able to control electrical switch, valve, motor, water pump and so on by hand.

6. Extraordinary Configurations

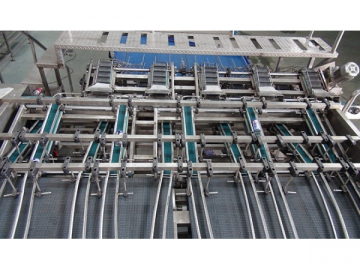

The key parts and accessories adopt imported materials from foreign brands, such as water pump, reduction box, net chain, net belt, visual inspection system, hydraulic control, electrical control and so on, ensuring stable performance and long service life.

The continuous sterilization equipment need no crate-loading machine, saving 50% of steam and about 25% to 40% of floor space. Besides, PLC is in charge of pressure and temperature control, and visual inspector can automatically overturn cans and keep them in order.

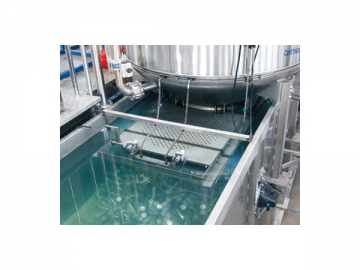

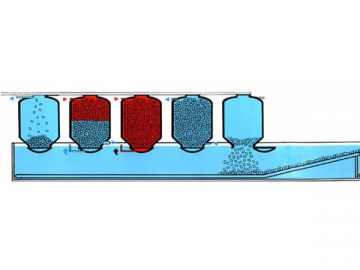

1. Loading: first, pump in hot water (used as cushion water for loading), and then load cans and keep overflowing at the same time

2. Steam inletting: cushion water is pushed out by steam from top inlet.

3. Venting and sterilizing: discharge water and air from the bottom.

4. Cooling: fill the retort with water from bottom inlet, and keep overflowing from top outlet if necessary.

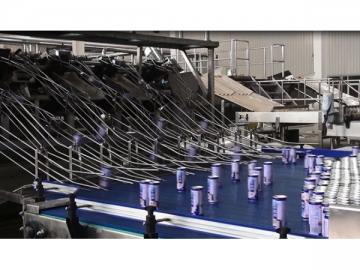

5. Discharging: cans are delivered via unscramlber after being discharged.

Technical Parameters of Crateless Retorts

1. Production speed of one retort

600 cans per hour (5133 type can)

2. Equipment dimensions

Length: 45.2m

Width: 5.48m

Height: 6.2m

Hot water kettle capacity: 17.5 m3

Process kettle capacity: 117 m3 /unit

Sterilization kettle capacity: 8.6 m3 / unit

3. Energy condition

Power: 28kw

Steam pipeline: DN80 per unit, 0.6-0.8Mpa steam pressure

Air compression: DN25, pressure: 0.8Mpa

Cooling water pipeline: DN100, pressure: 0.2Mpa

Applications

The continuous sterilization equipment is extensively used to sterilize canned beverages, vegetables with low acid content, such as tomato, soup, pet food, fish, meat, etc.