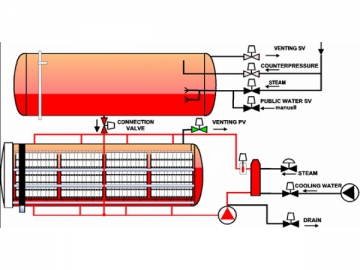

Water Immersion Retort

Actively involved in the sterilization equipment industry for many years, DTS is confident to introduce you the top-quality water immersion retorts. The rotary sterilizer retorts stand out with balanced heat distribution, automated operation and satisfactory sterilizing efficiency, the retort with hot water vessel and sterilization vessel is well suitable for various high-viscosity products packaged with thermal resistant materials.

Being the leading sterile retort maker in China, DTS is dedicated to providing top-notch batch retorts, continuous retorts, static retorts and rotary retorts for such industries as food, beverage and pharmacy. If you are interested in the automated rotary retorts or other retorts, please feel free to contact us.

Features of Water Immersion Retorts

1. Hot water is stored in upper kettle.

2. Due to full water immersion, heat can penetrate into products all around.

3. The automated rotary retorts can avoid air contact during the whole process, leading to zero cold air in kettle. The top-notch water circulating system ensures balanced heat distribution in kettle.

4. Peak pressure value can be avoided by controlling back pressure via stream inlet and outlet, largely reducing packaging material damage.

5. Smooth and rapid cooling helps the water immersion retorts avoid thermal shock and peculiar smell.

6. During heating, heat will penetrate into products at rapid speed, ensuring required sterilization performance can be achieved and designated F value can be reached at fast speed.

7. Thanks to forced convection brought by rotation, there is no cold point inside packages.

8. Full water immersion leads to satisfactory buoyancy, minimizing friction and collision of product packages.

9. Rotation during heating can help effectively avoid overheating of packaged food, container damage, over-steaming of product outer layer, delamination and precipitate.

10. The rotary batch retort is able to ensure the most ideal heat transfer performance. Short-time sterilization under high temperature can significantly improve efficiency and process more products.

| Item | Unit | 1500# | 1800# | ||

| Retort inner diameter | mm | 1500 | 1500 | 1800 | 1800 |

| Retort chamber length | mm | 4000 | 4850 | 6300 | 7500 |

| Total volume | m³ | 7.5 | 9 | 16.7 | 19.9 |

| External dimensions(L*W*H) | mm | 5800*2510*2270 | 6650*2510*2270 | 8600*2700*2400 | 9800*2700*2400 |

| Power | kw | 18 | 18 | 27.5 | 27.5 |

| Design temperature | °C | 145 | |||

| Operating temperature | °C | 125 | |||

| Test pressure | MPa | 0.44 | |||

| Design pressure | MPa | 0.35 | |||

| Operating pressure | MPa | 0.25 | |||

| Materials for main pressure-bearing parts | S30408 Q235B 20# Q345R | ||||

Applications

The water immersion retorts are ideal for all kinds of high-viscosity products packaged with thermal resistant materials.

1. Plastic container: PP bottle, HDPE bottle

2. Metal container: tin can