Underwater Anchoring Adhesive, MT-500/W

Structural Adhesives

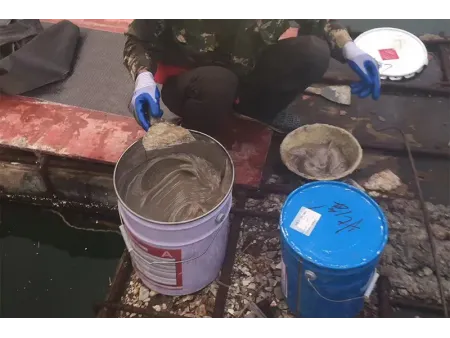

Two-component adhesives for anchoring threaded rods and reinforcing bars in humid and underwater environments

The underwater anchoring adhesive is a two-component injectable epoxy system, designed for reliable anchoring of threaded rods, rebar, or anchor bolts in wet, humid, or fully submerged concrete environments. Dispensed through a static mixing nozzle using a standard applicator, the system ensures accurate on-site mixing and easy installation, even in challenging conditions.

This formulation features strong seawater resistance and can fully cure underwater without dispersion or performance loss. Its anchoring strength under submerged conditions is equivalent to that achieved in dry concrete. The adhesive addresses a key limitation of conventional epoxies by resisting water absorption and maintaining long-term bond strength in underwater applications, making it a durable choice for marine structures, piers, tunnels, and waterfront infrastructure.

Meets the technical performance requirements of GB 50728-2011 - Technical Code for Safety Evaluation of Reinforcement Materials for Engineering Structures

| Property | Standard Requirement | Test Result | |

| Steel-to-steel tensile shear strength | Cured underwater for 7 days,tested immediately at 5°C | ≥10MPa | 13.8MPa |

| Cured underwater for 7 days,air-dried for 3 days,then soaked underwater for 30 days and tested immediately | ≥8MPa | 12.8MPa | |

| Steel-to-steel T impact peeling length | ≤25mm | 15.7mm | |

| Resistance to salt water soaking | 90d soaking | Steel-to-steel tensile shear strength reduction after 90-day saltwater soaking remained below 10% compared to the unsoaked control sample | 7.6 |

| Steel-to-C45 concrete positive tensile strength | - | 3.10MPa,with cohesive failure of concrete | |

| Temperature | Installation Time | Gelling Time | Full Curing Time |

| -5℃~0℃ | 30min | 80~150min | 168h |

| 0℃~10℃ | 20min | 50~80min | 120h |

| 10℃~25℃ | 10min | 30~50min | 72h |

| 25℃~40℃ | 5min | 10~30min | 48h |

| ≥40℃ | 3min | 5min | 24h |

| Appearance | Component A:Brownish-yellow paste | Component B:Brownish-green paste |

| Mixed (A B):Green paste | ||

| Mixing Ratio | Component A:Component B = 2:1 (by volume) | |

| Mixed Density | 1.48g/cm³ | |

| Application Temperature Range | Minimum:5 °C | |

| Maximum:35 °C | ||

| Working Time | 5℃:50 mins | |

| 20℃:25 mins | ||

| 35℃:10 mins | ||

| Storage Conditions | Store sealed in a cool,dry,and well-ventilated environment at ambient temperature Shelf life:18 months | |

- Easily applied by injection, with consistent mixing through a static mixer

- Resistant to acids, alkalis, and creep, ensuring stable long-term anchoring

- Thixotropic formulation prevents sagging during application and provides excellent adhesion to most structural materials

- Non-crystallizing and moisture-resistant, capable of curing at low temperatures with demonstrated aging resistance over 50 years

- Withstands seawater exposure for underwater anchoring and repair

- Proven seismic, impact, and fatigue resistance, tested to 2 million cycles

- Meets all technical performance criteria for Grade A structural adhesive as specified in relevant standards

- Non-toxic and non-flammable, safe for handling and transport by all standard logistics methods

- Suitable for bonding and anchoring between steel, concrete, and other metal materials in underwater conditions

- Used for underwater repair, structural reinforcement, sealing, and crack filling

- Designed for reliable performance in submerged, damp, or dry environments, ensuring long-term service durability across marine, tunnel, and foundation works

- Packaging: 16 cartridges per box, with a net capacity of 500 ml per cartridge

- Gross weight: Approximately 14.9 kg per box

- Carton dimensions: 380 mm × 190 mm × 290 mm (L × W × H)

- Shelf life: 18 months when stored in standard room temperature conditions

- Storage requirements: Keep away from direct sunlight, open flames, and heat sources

Confidential underwater anchoring project in Beihai

Underwater rebar anchoring at Hongqili Bridge, Zhongshan