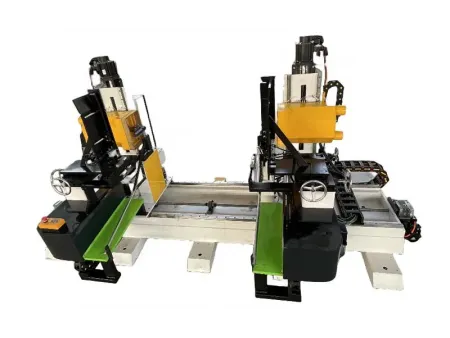

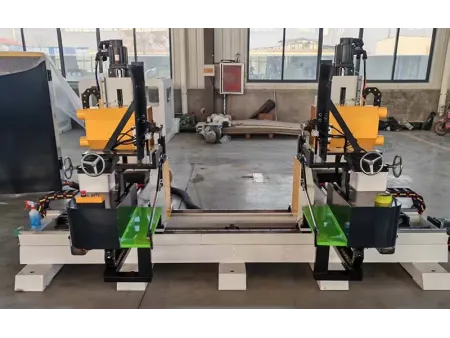

Double-End Tenoner

Request a Quote

//Woodworking Machinery

Double-sided tenoning machine for simultaneously producing rectangular and circular tenons on both ends

Woodworking Machinery

- Max. vertical angle30°

- Spindle speed10000r/min

- Machine weight1500kg

- Machine dimensions (L×W×H)3500×1800×1800mm

The double-end tenners can simultaneously process both ends of a workpiece, significantly increasing production efficiency in joinery and frame manufacturing. It supports a wide range of tenon types and ensures precise alignment and strong joint integrity between connected components. This tenoning machine is ideal for producing wood parts that require consistent, dual-end tenoning in applications such as furniture, doors, windows, and architectural woodwork.

Specifications

- Max. diameter of round tenon80mm

- Max. diameter of rectangular tenon150×80mm

- Max. width of transverse tenon150mm

- Max. width of vertical tenon80mm

- Max. width of slant tenon150mm

- Max. vertical angle30°

- Max. transverse angle45°

- Hopper height550mm

- Working width150-2000mm

- Air pressure0.4-0.9MPa

- Dust suction inlet diameterØ98mm×2pcs

- Spindle speed10000r/min

- Spindle power5.5kW×2pcs

- ControllerPLC

- Total power12.0kW

- Machine weight1500kg

- Machine dimensions (L×W×H)3500×1800×1800mm

Applications

Suitable for machining a variety of tenon types including round tenons, rectangular tenons, horizontal tenons, straight tenons, sloped tenons, and angled shoulder joints. It supports flexible processing to accommodate diverse structural and design requirements.