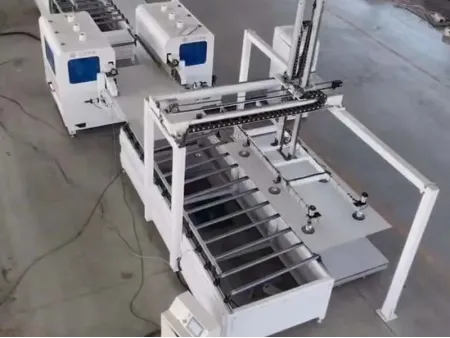

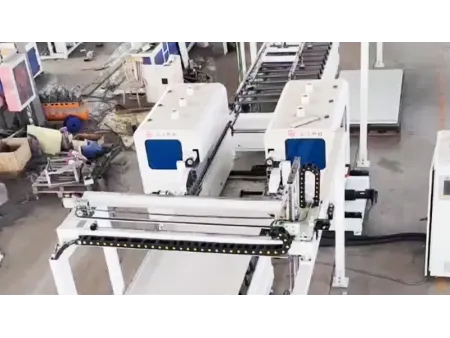

CNC Wall Panel Edge Slotting Machine (Double Side)

Request a Quote

//Woodworking Machinery

Wood processing machine for cutting slots on both edges of wood panel

- Spindle motor power5.5kW×2pcs

- Saw motor power1.1kW

- Travel motor power2.2kW

- Machine weight2500kg

CNC Double-Side Slotting Machine

CNC double-side edge slotting machines perform simultaneous precision slotting on both longitudinal edges of wall panels and composite boards in a single pass. Equipped with six axes and three tooling stations on each side, all driven by servo motors for synchronized high-precision operation, these systems deliver rapid and accurate slotting, making them ideal for industrial-scale panel processing.

Application

Perfect for slotting operations on a variety of materials, including:

- Carbon crystal panels

- Wood veneer panels

- Stone-plastic composite (SPC) boards

- Aluminum-plastic composite panels

- Various multi-layer composite boards

Specifications

| Model | ||

| Spindle motor power | 5.5kW×2pcs | 5.5kW×2pcs |

| Saw motor power | 1.1kW | 1.1kW |

| Cutter motor power | 3.5kW×2pcs | 2.2kW |

| Servo motor power (fixed width) | 1.5kW | 1.5kW |

| Servo motor power (cutter) | 0.75kW×8pcs | 0.75kW×8pcs |

| Travel motor power | 2.2kW | 2.2kW |

| Machine dimensions (L×W×H) | 3500×2300×1800 | 3000×2300×2400 |

| Machine weight | 2500kg | 2500kg |

Features

- The slotting machine frame is fully welded and undergoes a 24-hour heat treatment to eliminate internal stress, ensuring long-term structural stability without deformation. The motion system uses high-strength, widened dual linear guide rails, achieving linear accuracy within 0.03 mm. Additionally, the panel feeding system adopts a table-mounted chain block conveyor, significantly enhancing workpiece transport stability during machining.

- Equipped with servo-controlled width adjustment and automatic tool setting, the machine offers a fully integrated CNC operation, enabling straightforward and efficient use, often described as fool-proof operation that is user-friendly and easy to operate.

Robotic Loading and Unloading System

- Overall dimensions (L×W×H) 4400×2300×2500mm

- Machine weight 1500 kg

- Servo motor power 0.75 kW×2 (for linear transfer and gripping)

- Variable frequency motor 1.1 kW×1 (for adjustable travel speed)

- Travel speed 5–50 m/min (servo-controlled, adjustable via touchscreen interface)

Function

- Positioning & separation: Accurately aligns and separates each panel.

- Steady transfer: Uniform, continuous forward movement of panels into the next machining phase.

Sample Showcase