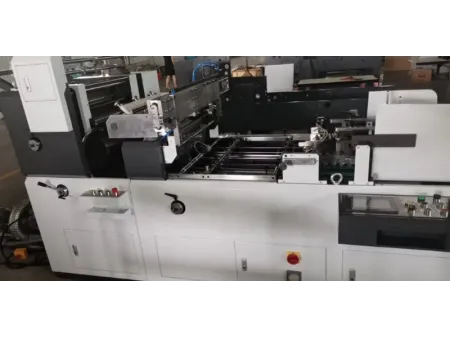

Window Patching Machine

Request a Quote

The window patching machine is designed with two independent feeding stations, allowing operators to prepare the next stack of sheets while the first station continues running. This setup significantly improves continuous production and overall output.

Structure

Sheet Feeding Section

Window Patching Section

Cutting Section

Board Conveying Section

Technical Specifications

| Model | ZM-STC650 |

| Max. paper feed size, mm | 650x650 |

| Min. paper feed size, mm | 100x100 |

| Max. patch size, mm | 380x450 |

| Min. patch size, mm | 40x60 |

| Film thickness, mm | 0.05-0.25 |

| Cardboard application range, g/m² | 200-1000 |

| Corrugated board thickness, mm | ≤ 4.0 |

| Max. mechanical speed, sheets/h | 10,000 |

| Total power, kW | 8 |

| Machine weight, T | 2 |

| Machine dimensions (LxWxH), mm | 4750x1550x1600 |

Is the feeding station configuration optional?

Yes. Depending on production needs, the machine can be equipped with either a single feeding station or a dual feeding station.

What heating methods are available when purchasing corrugated board equipment?

Available heating options include steam heating (requires steam boiler), electric heating (built-in heating rods), thermal oil heating (requires thermal oil furnace), natural gas / LPG heating (built-in burner), and oil-electric hybrid heating (built-in system).