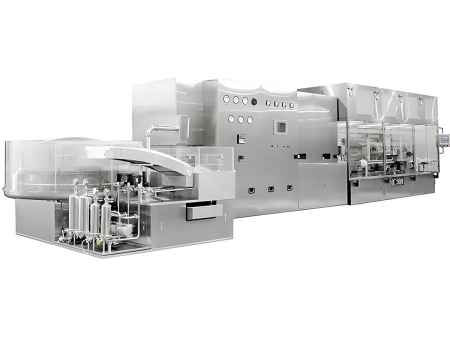

Ampoule Washing, Drying, Filling and Sealing Machine

The BXAZ ampoule washing, drying, filling and sealing machine is the pharmaceutical equipment that is newly designed and manufactured using cutting edge technologies and our patent technologies. With reasonable design, compact structure, high automation, reliable operation and high efficiency, the unit has achieved an internationally advanced level.

The unit is composed of CLQ ultrasonic cleaning machine, RSM glass ampoule sterilizing drying machine and AGF ampoule filling and sealing machine. These machines can be used independently or used in combination with each other, according to customers' actual requirements.

-

Applicable Specification 1-20 ml ampoule vials

-

Capacity 15000 pcs/hour

| Applicable Specification | 1-20 ml ampoule vials |

| Capacity | 15000 pcs/hour |

| WFI Consumption | 0.4 m3/h 0.2-0.3 Mpa |

| Compressed Air Consumption | 30 m3/h 0.4 Mpa |

| Gas Consumption | 300L/h 2-3×104 pa |

| Oxygen Consumption | 900 L/h 2-5×104 pa |

| Sterilizing Temperature | 320 ℃ (adjustable) |

| Bottle Breakage Rate | ultrasonic cleaning machine ≤ 0.5 %, ampoule filling and sealing Machine ≤ 0.5 % |

| Filling Accuracy | ± 2 % |

| Noise | ≤ 80Db (A) |

- The ampoule washing, drying, filling and sealing machine protects the vials from contamination throughout the whole production process as all operations are completed under clean environment.

- The combination of ultrasonic cleaning and water, gas jet cleaning ensures good cleaning result.

- The adoption of ultra filtration technology in the filter apparatus of washing machine helps achieve sterile clean water and compressed air after terminal filtering. This makes improved bottle clarity possible.

- The washer adopts high power ultrasonic apparatus. The power can be adjusted to accommodate vials of different specifications.

- The machine uses double water tank. The circulation tank and rough washing tank are totally separated. The wash water at each stage is filtered for downgrade usage.

- The use of single side fixing stainless steel manipulator to grip vials makes positioning more accurate. The grippers are wear resistant and long lasting.

- Without lifting device, the machine utilizes star wheel to facilitate bottle feeding. The simpler structure contributes to lower failure rate and more stable operation.

- The sterilizing drying machine uses hot air laminar flow sterilizing principle to sterilize vials with even distribution of heat.

- The high efficiency filters in the purification chamber undergo negative pressure sealing process and they are easy to mount, ensuring class 100 cleanliness conditions.

- The articulated heater and horizontal hot air generator structure makes maintenance more convenient and labor saving.

- The adoption of chain belt with sideboard avoids bottle falling and breakage caused by belt offtrack and crawling.

- The drying tunnel is equipped with belt cleaning device, which helps keep the vials clean.

- The filling and sealing machine adopts multi-needle filling, nitrogen filling and draw-sealing techniques.

- It features balcony type structure. The star wheel ensures continuous vial feeding with low breakage rate.

- The driving parts are in a closed condition, so they are unlikely to be eroded by liquid medicine.

- The ampoule washing, drying, filling and sealing machine can be easily and quickly adapted to accommodate ampoule vials of different specifications. In addition, replacing few mold and star wheel can change this unit into a penicillin bottle washing, filling and sealing machine.

- Single machines of the unit all adopt PLC, human-machine interface to control and monitor the operating status. These control systems can operate separately or cooperate with each other to realize linkage control.

- The parts that come into contact with liquid medicine are made of 316L stainless steel, quality silicone tube or glassware. Other parts are manufactured using materials that can meet the equipment function requirements and GMP requirements.

- The unit can be configured according to customers' actual demands.

As a China ampoule washing, drying, filling and sealing machine manufacturer, at IVEN Pharmatech we also offer non-PVC infusion bag IV solution production line, vial filling and stoppering machine, auto light inspection machine, and more.