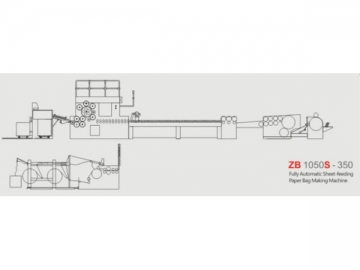

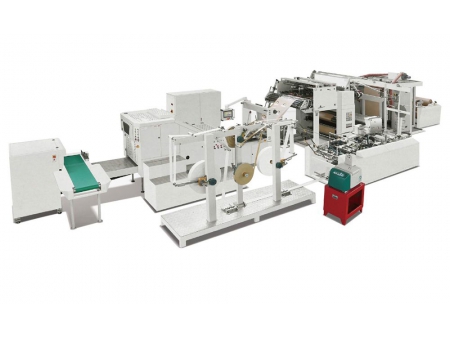

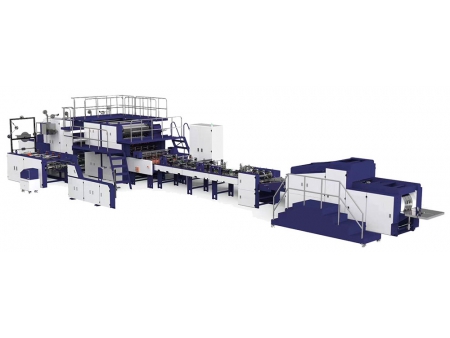

ZB450J Roll-Feeding Paper Bag Making Machine

ZB450J Roll-Feeding Paper Bag Making Machine

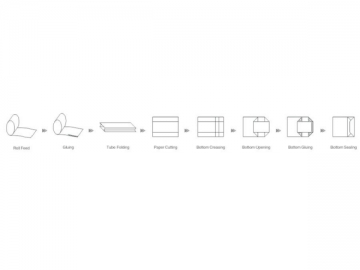

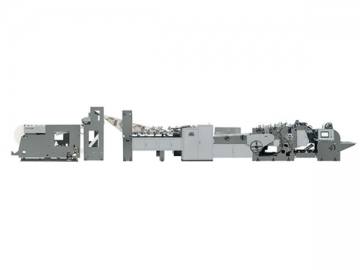

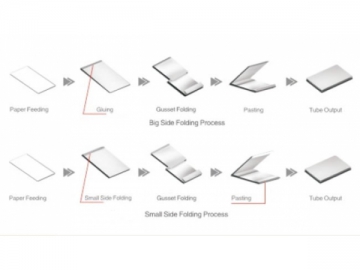

The ZB450J roll-feeding paper bag making machine is suitable for massmanufacture of handbags by taking reel paper as raw materials. As anintegration of mechanical, electric, pneumatic and photoelectric devices, this paper bag manufacturingmachine can implement the process of gluing, tube forming, gussetfolding, slitting, creasing, bottom folding, bottom sealing, bag pressing andoutput at one stroke to primary color or printed web. In addition, controlledby central computer, it can achieve traceless bottom forming, thus ensuringperfect quality.

Configurations and Features

1. Feedingunit. The reel paper bag forming machine is equipped with a specialfeeder which supports automatic feeding and tension controlling, thus ensuringfast feeding, easy control and simple operation.

2. Cutting unit. This paper bag making machine comes with a centralcomputer controlled cutting device which can automatically set bag length, thuskeeping ±

3. Bottom separation function. This enables separate commissioning of thetraction and bottom gluing units, thus reducing waste.

4. Bottom pasting unit. This paper shopping bag making machine adopts the latest bottomsealing process which contributes to the manufacture of traceless paper bags.Furthermore this process boasts several utility model patents, hence ensuringperfect quality.

5. Gluing system. The paper bag making machine comes with a watersoluble cold glue gluing unit.

6. Color code tracking function. During the process, colorcode of the printed reel paper can be automatically tracked so as to keepaccurate size of each bag.

7. Screw rod adjusting unit. When it is needed to manufacture different specifications of paperbags, the advanced screw rod adjusting device can be used to shorten machineadjusting time so as to improve production efficiency.

8. Automatic bag collecting unit. The paper pouchmaking machine can achieve automatic bags collecting and countingin mass production.

Main Technical Parameters

| paper width | 1230-600mm |

| Output bag length | 270 |

| Output bag width | 260 |

| Bottom width | 80 |

| Base paper weight | 90 |

| Max. reel diameter | Φ |

| Base reel inner diameter | Φ |

| Max speed | |

| Total Power | 18.5kw |

| Outline dimensions(L×W×H) | 11900×2500× |

| Total weight | 8T |

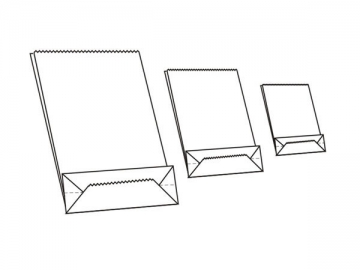

Suitable paper: Kraft paper, art paper, (including film adhesive paper)

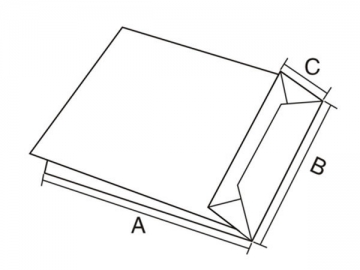

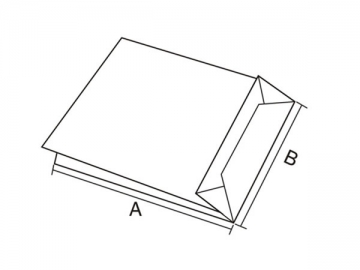

| A | B | C | |

| Max. Size(mm) | 150 | 430 | 470 |

| Min. Size(mm) | 80 | 260 | 270 |