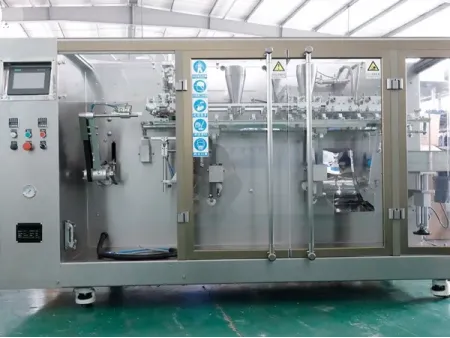

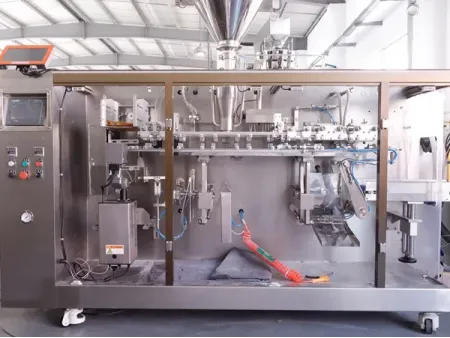

Premade Pouch Packaging Machine, 1-Nozzle Filling

Designed for small production runs and a wide variety of lightweight products, these single-nozzle premade pouch packaging machines focus on flexibility and easy operation. The servo-driven system keeps the filling and sealing processes stable, and the compact layout helps save floor space while allowing pouch sizes to be changed quickly. Due to their steady output of around 40–60 pouches per minute, these pouch filling and sealing systems are ideal for candies and other lightweight products, especially in small-batch production where frequent format changes and consistent filling quality are needed.

Applications

Supported Pouch Types

- Flat pouches

- Flat pouches

- Stand-up pouches (doypack)/Zipper pouches

- Stand-up pouches (doypack)/Zipper pouches

- Shaped pouches

- Spouted pouches

- Pouch loading

- Pouch pick-up

- Pouch opening detection

- Bottom opening

- Filling

- Pouch spreading

- Heat sealing

- Seal cooling

- Finished pouch forming

- Finished pouch discharge

- Small batches can be produced at a relatively high speed, reaching up to 60 pouches per minute, while keeping the output stable over long production runs.

- A user-friendly interface with a color touch screen makes settings easy to understand and adjust and allows operators to monitor the machine status in real time.

| Model | 180NG |

| Applicable pouch size | (Min) 60x130mm (Max.) 180x250mm |

| Max. Filling volume | 1000ml |

| Packaging speed | ≤60 |

| Machine dimensions | 2400mmx1100mmx1400mm |

| Machine weight | 800kg |

| Installed power | 3.5kw |

| Air consumption | 300L/min |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

A well-known food company in Russia began working with us in 2023 and purchased a single-nozzle premade pouch packaging machine for mayonnaise. The pouch packaging equipment is now used for spouted stand-up pouches with a filling weight of 750 g, supporting stable and consistent filling for this type of viscous product.