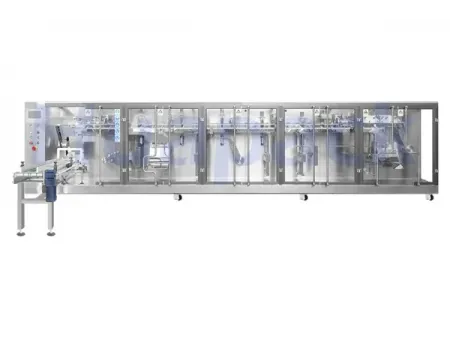

Premade Pouch Packaging Machine, 1-Nozzle Filling

Designed for high-output production and large orders, these horizontal premade pouch packaging machines handle filling volumes of up to 1500 ml and can work with pouch-in-pouch formats, where a separate inner pouch is accurately placed inside the main outer pouch to create a double-layer package. They have an structure that is useful for special applications, such as packing two reactive components separately in the chemical industry so they only mix at the point of use. An intelligent control system manages the filling of the inner and outer pouches independently, which allows different products and filling sequences to be set and controlled with good accuracy and stable operation.

Applications

Supported Pouch Types

- Flat pouches

- Flat pouches

- Stand-up pouches (doypack)

- Stand-up pouches (doypack)

- Pouch loading

- Pouch pick-up

- Pouch opening detection

- Bottom opening

- Filling

- Pouch spreading

- Heat sealing

- Seal cooling

- Finished pouch forming

- Finished pouch discharge

| Model | 460NG |

| Pouch width range | 90–460 mm |

| Pouch height range (stand-up pouch) | 130–350 mm |

| Max. filling volume | 1500 ml |

| Machine dimensions (L × W × H) | 4900 × 2600 × 1400 mm |

| Operating temperature | –10 °C to 55 °C |

| Operating humidity | ≤ 85% RH |

| Power supply | AC 380 V, 50 Hz |

| Air pressure | 0.6 MPa |

| Air consumption | 560 L/min |

| Installed power | 8.5 kW |

| Machine weight | 3500 kg |

| Operating speed | Up to 80 pouches/min |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

To support large production volumes and higher filling weights, a dairy company located in Tianjin invested in our 460NG premade pouch packaging machine in 2022. Since installation, the pouch packaging machine has been used to handle heavy-duty filling tasks while maintaining stable output and consistent pack quality for mass-market dairy products.